Introduction

Manufacturing execution (ME) is about immediate insight into what happens, letting workers know what to do, and about providing the required information to instruct and guide workers. Additionally, ME provides the ability to record costs, monitor performance, and trace the history of production, which is critical to the manufacturing execution process.

Manufacturing execution is primarily intended for use by manufacturing companies. Workers can register time and item consumption on production jobs and project activities by using the Job registration page.

All registrations are approved and subsequently transferred to the relevant Dynamics 365 Supply Chain Management modules. Continuous approval and transfer of registrations give managers the ability to easily track actual costs on production orders.

Manufacturing execution serves several purposes in a manufacturing company, including:

Resource management - Includes the basic information about the resources (tools, machines, workers, or vendors) and their capacity, capabilities, and requirements. The goal is to schedule and process production orders with resources that have the correct capabilities and availability.

Production scheduling - The scheduling process uses all the information that is available from resources and the inventory and master planning sub systems to determine how much to produce and then how to make optimal use of the available resources to meet the demand requirements.

Production order processing - Although the actual implementation of the production order is completed in the Production control module, ME integrates with the Production control module to provide the details about the time and materials that are consumed for specific jobs or operations.

Performance analysis and tracing - ME tracks the detailed status of a production order. This analysis and tracing is useful in providing accurate work-in-progress (WIP) information, resource performance statistics, or other performance indicators. It also provides the ability to trace the complete history of the orders, batches, or serial numbers that are processed.

Several pages that are directly related to Manufacturing execution can be found in the Production control module. The following list includes several of these pages.

Production control > Manufacturing execution > Jobs and activities > Production job

Production jobs - Displays a list page with all the production jobs that are released to Manufacturing execution.

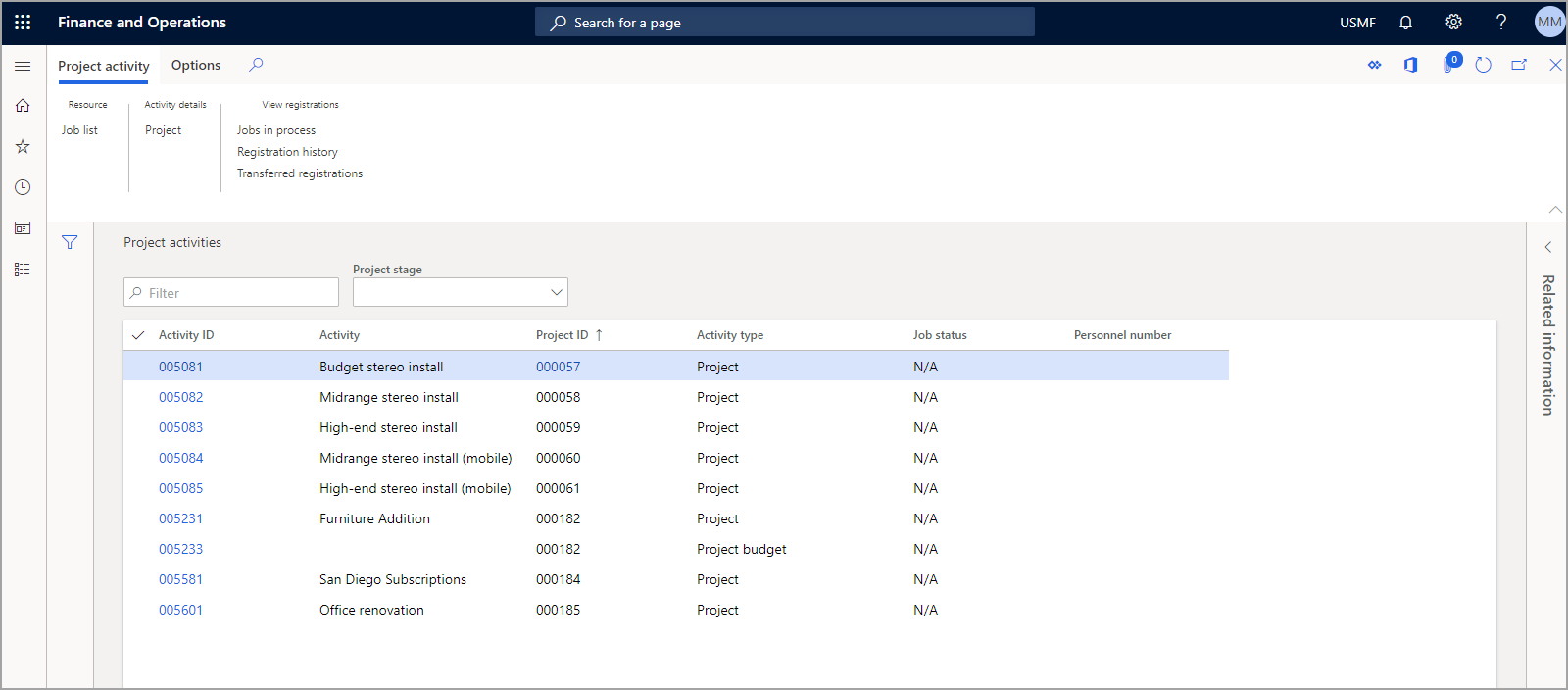

Project activities - Displays a list page with all the project activities that are released to Manufacturing execution.

Go to Production control > Manufacturing execution > Handle messages to create and manage messages that will appear on the Job registration page.

Production control > Inquiries and reports > Manufacturing execution > Raw registrations

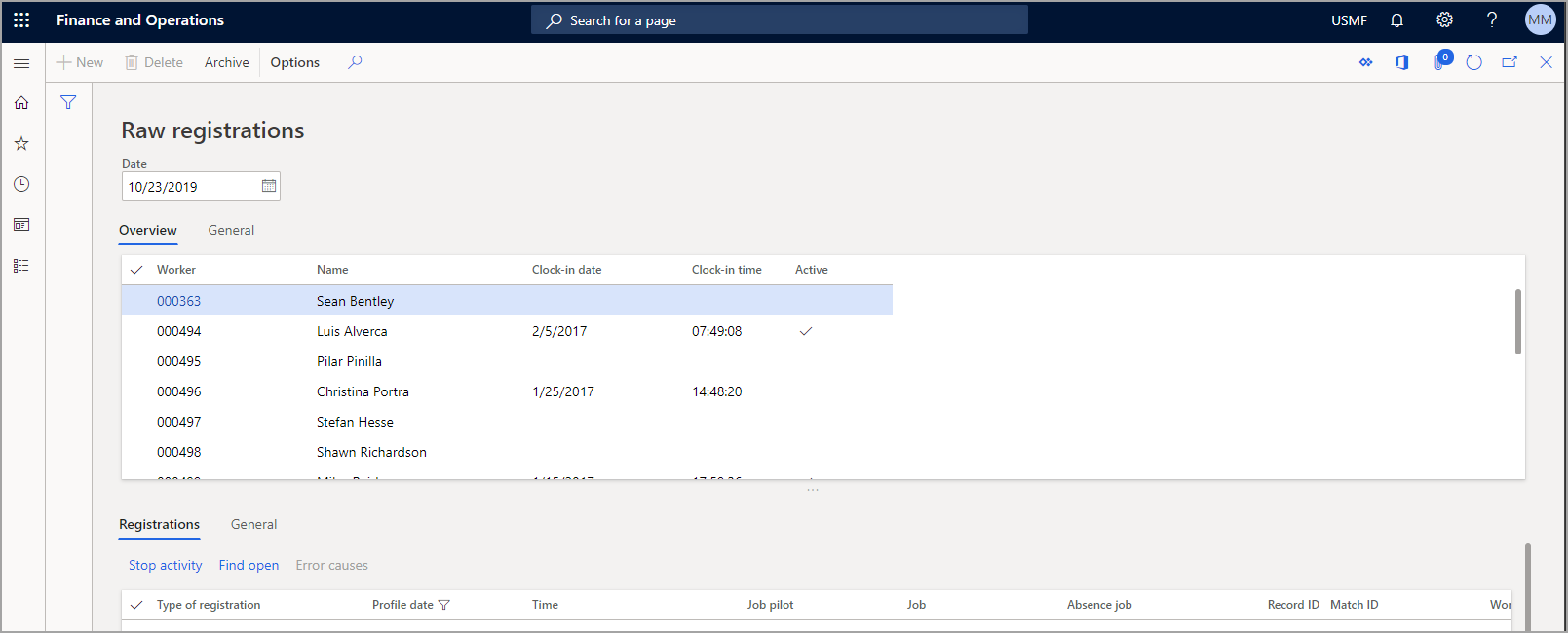

Raw registrations - Displays a list of all registrations that are not archived.

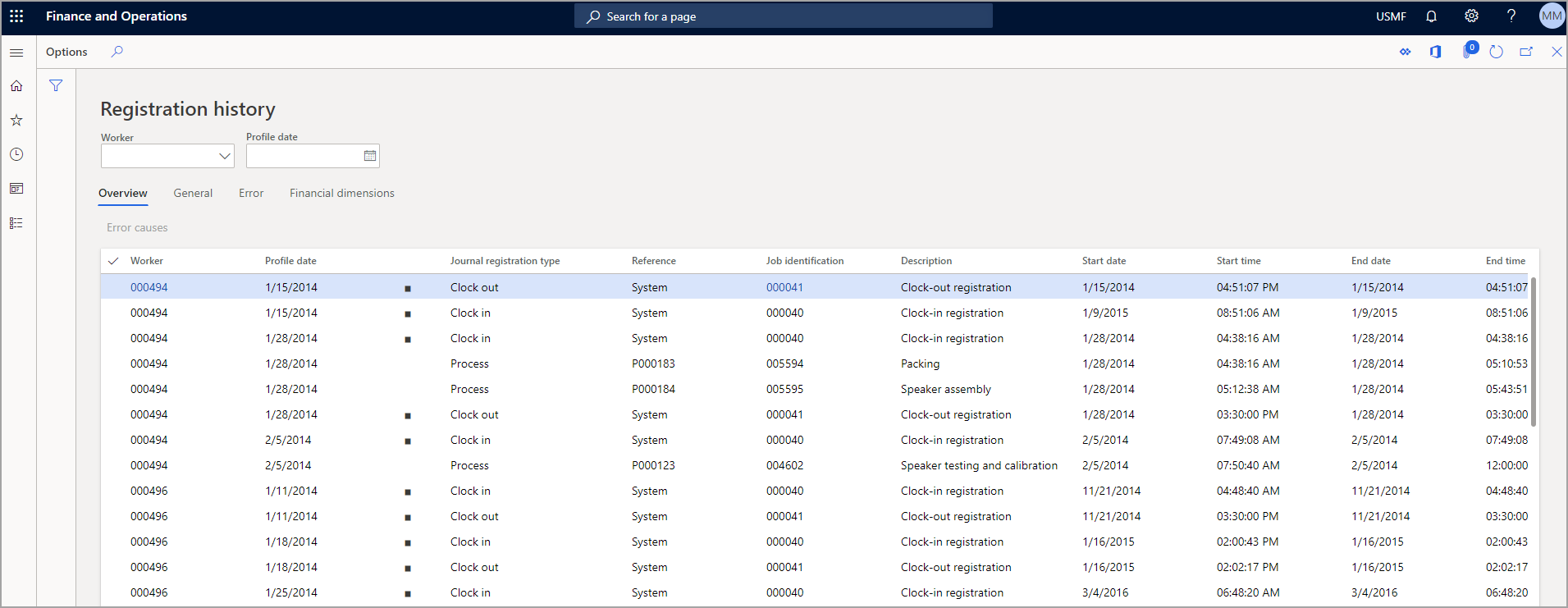

Registration history - Displays a list of registrations that have been modified and their details.

Posted registrations - Displays a filtered list of registrations that are approved and posted.

Raw registrations archive - Displays the list of registrations that have been archived.

Production control > Setup > Manufacturing execution > Manufacturing execution parameters

Manufacturing execution parameters - Sets up manufacturing execution parameters in the Production control module.

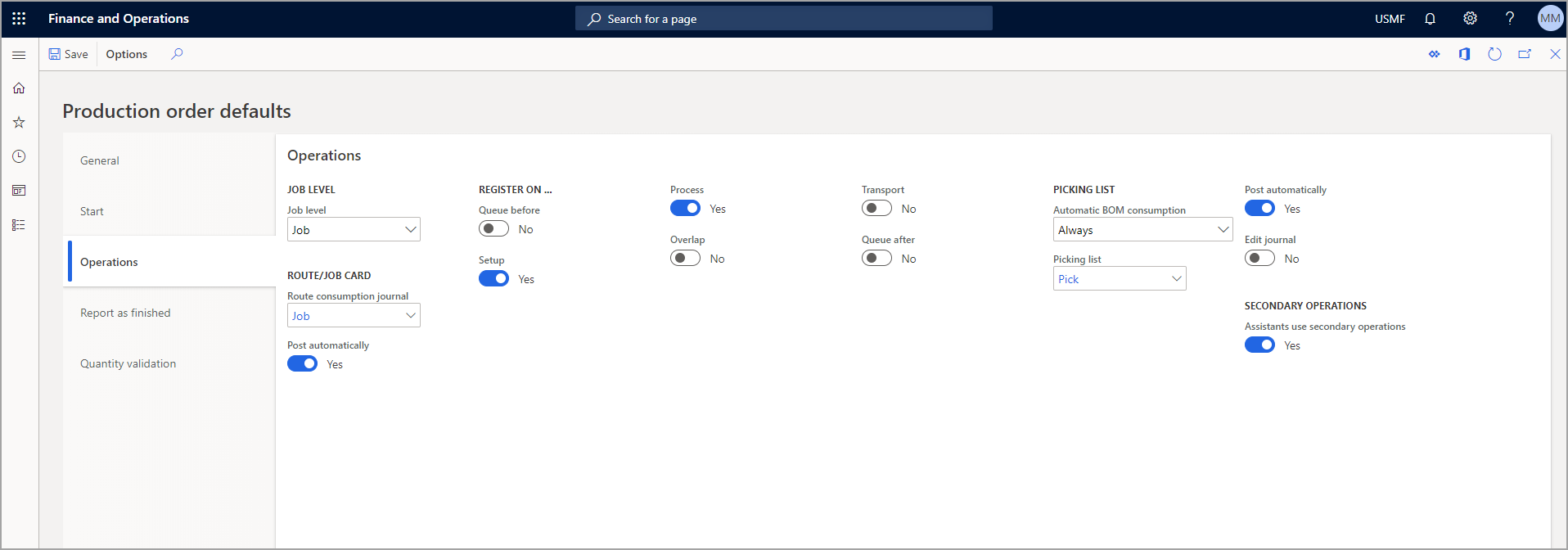

Production order defaults - Defines parameters that integrate the Manufacturing execution features with the Production control module.

Production order defaults by site - Defines site-specific parameters that integrate the Manufacturing execution features with the Production control module.

Configure job card terminals - Edits existing registration pages and configures new registration pages.

Configure job card for devices - Displays a list of existing devices. You can also use this page to change the parameters for a device.

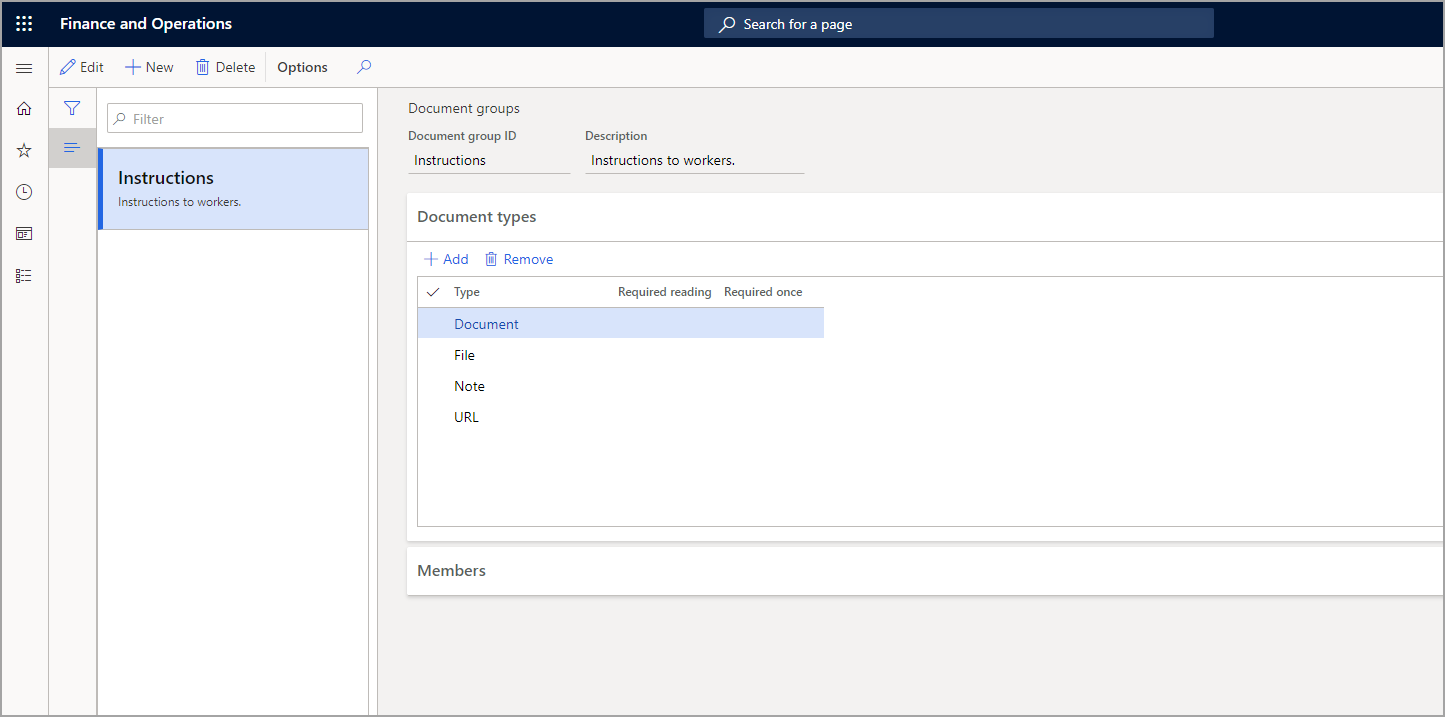

Production control > Setup > Document groups - Sets up document groups. The groups define which workers can read different document types.

Production control > Setup > Production > Allocation keys - Defines which allocation key to apply to packaged job registrations within a specific area.

.

. .

. .

. .

. .

. .

. .

. .

. .

.