Inventory Control in Dynamics GP - Parts 1-3

You can use Inventory Control to help manage your company's inventoried items. Many Inventory Control tasks help you create records for your items, such as how the items are to be tracked and what pricing should be used for the items that are sold. Parts 4 and 5 are in Inventory Control in Dynamics GP - Parts 4-6.

You also can use Inventory Control to complete the following tasks:

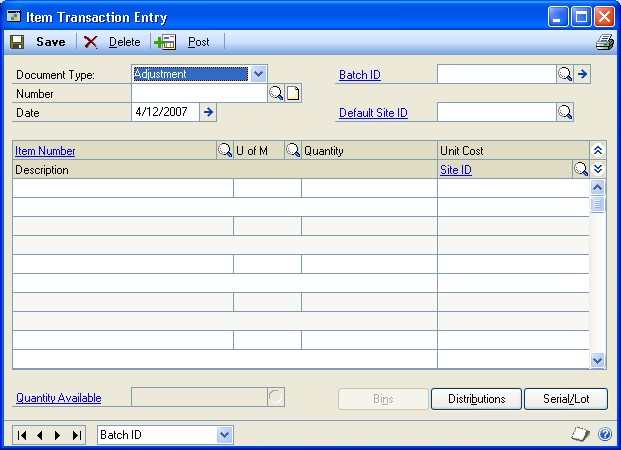

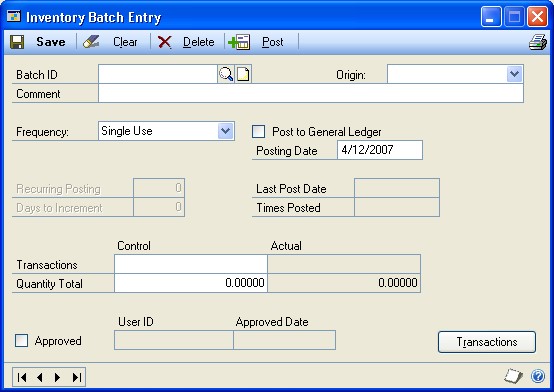

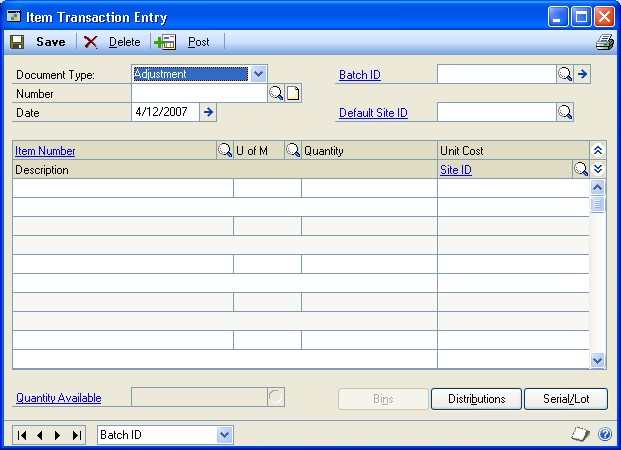

Enter and post adjustment transactions and variance transactions individually or in batches

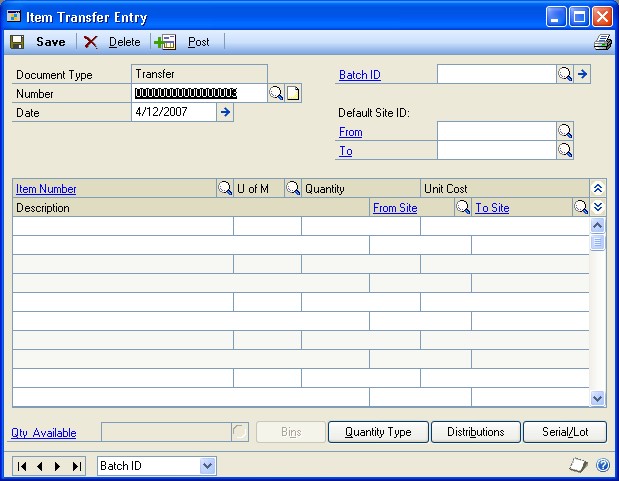

Enter and post transfer transactions individually or in batches

Complete stock counts, which include both cycle counts and physical inventory counts

Use ABC analysis to prioritize items

Print the Historical Stock Status Report

Trace the life cycle of a serial number or lot number

Track a single inventory item across multiple bins within the warehouse

This manual is designed to give you an understanding of how to use the features of Inventory Control, and how it integrates with the Microsoft Dynamics® GP system.

To make best use of Inventory Control, you should be familiar with systemwide features described in the System User's Guide, the System Setup Guide, and the System Administrator's Guide.

Some features described in the documentation are optional and can be purchased through your Microsoft Dynamics GP partner.

To view information about the release of Microsoft Dynamics GP that you're using and which modules or features you are registered to use, choose Help >> About Microsoft Dynamics GP.

The manual is divided into the following parts:

Part 1: Setup, describes the tasks you must complete to set up inventory, such as specifying system settings and setting up unit of measure schedules and item classes.

Part 2: Cards, includes information about basic inventory records. Refer to that part to learn how to define, modify, and remove items, sites, and kits. Information about setting up pricing structures also is included.

Part 3: Transactions, contains information about entering and posting inventory transactions and transfers.

Part 4: Inquiries and reports, describes windows and reports you can use to view your inventory information. For more information, see Part 4: Inquiries and reports.

Part 5, Utilities, includes information about completing special tasks, such as using price list wizards, reconciling inventory, removing history records, and adjusting average costs of items. For more information, see Part 5: Utilities.

Part 6, Routines, describes how you can use inventory checklists. Information about year-end closing tasks is also included. For more information, see Part 6: Routines.

Part 1: Setup

Use the following information to set up Inventory Control. Setup procedures generally need to be completed once, but you can refer to the information at other times for instructions on modifying or viewing existing entries.

Note

You'll need to complete these setup procedures before using the procedures in Part 2, Cards, which describes how to create item records, and Part 3, Transactions, which describes accounting tasks specific to Inventory Control.

The following information is discussed:

Chapter 1, "Overview," describes how Inventory Control integrates with other modules, and discusses basic terms and concepts.

Chapter 2, "Setup preparation," explains tasks you must complete before you can begin setting up Inventory Control.

Chapter 3, "Preferences and default settings," contains information about setting preferences and default settings.

Chapter 4, "Unit of measure schedules," includes information about creating, modifying, and deleting unit of measure schedules.

Chapter 5, "Standard pricing," describes how to set up and maintain price levels and price groups if you're using standard pricing.

Chapter 6, "Lot category setup," explains how you can use lot categories to track shared attributes of the items in a lot.

Chapter 7, "Item classes," contains information about setting up item classes, an optional step you can use to make defining new items quicker and more accurate.

Chapter 8, "Stock count calendar," describes how to create a stock count calendar.

*Chapter 9, "Reason codes,"*explains reason codes and how to create, modify and delete them.

Chapter 1: Overview

You can use Inventory Control to help manage your company's inventoried items. These can be any items needed for customer support, such as products or spare parts you sell; for business support activities, such as maintenance and repairs; or for use in creating your products, as in a manufacturing environment.

Many Inventory Control tasks help you create records for your items—how the items are to be tracked, what pricing should be used for the items that are sold, and so on. You also can use Inventory Control to enter and post certain types of inventory transactions, to create service items, and to set up and perform stock counts.

This document includes the terms and concepts you'll need to know to use Inventory Control.

The following information is discussed:

Dependencies and relationships to other modules

Item types

Valuation methods

Standard and extended pricing

Multiple bins

Stock count overview

Dependencies and relationships to other modules

When you use Inventory Control, you should be aware of how the module interacts with other modules.

Refer to the table for more information.

| Module or series | Affects inventory: | Uses inventory info: |

|---|---|---|

| Sales Order Processing | Sales transactions will decrease inventory amounts | Item records, quantities, and pricing information |

| Invoicing | – | Item records, quantities, and pricing information |

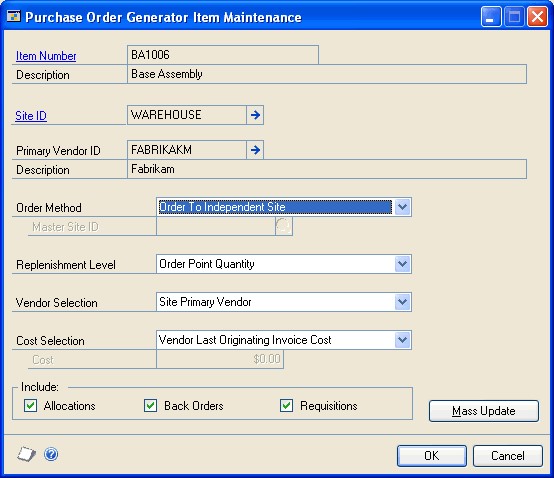

| Purchase Order Processing | Purchase transactions will increase inventory amounts | Item records, quantities, and vendor information. If you're using the purchase order generator or landed costs, the details for each item-site combination are entered in Inventory Control. |

| Bill of Materials | – | Item records |

| General Ledger | – | Posting |

Item types

Item types describe the type of item or the status of the item. These types also determine which posting accounts are updated when items are entered on transactions. Refer to the Purchase Order Processing or Sales Order Processing documentation for information about which accounts are affected when posting transactions for each item type. Use the following table to decide which item type to assign to an item or item class.

| Item type | Description |

|---|---|

| Sales Inventory | Quantities are tracked. You can enter both increase and decrease adjustments. Amounts posted to the Inventory and Inventory |

| Discontinued | Items are tracked the same as Sales Inventory items, selling Quantities On Hand. You can enter adjustments for the item, and can delete the item when the quantity reaches zero. Posting updates the Inventory and Inventory Offset accounts. Posting from Sales Order Processing affects the Sales, Cash, Cost of Good Sold, or Accounts Receivables accounts. If you don't want to sell discontinued items, be sure that the Allow Sale of Discontinued Items option is unmarked in the Sales Order Processing Setup Options window. |

| Miscellaneous Charges | Quantities and current costs aren't tracked in Inventory. |

| Kit | Quantities aren't tracked. Kits consist of one or more components, which can be services, sales inventory, miscellaneous charges, discontinued, or flat fee items. Based on the item type, posting updates the Inventory and Cost of Goods Sold accounts specified for each component. If you plan to create a phantom bill for use on a bill of materials, we recommend not assigning components to the Kit in Inventory. Posting from Sales Order Processing affects the Sales, Cash, Cost of Good Sold, or Accounts Receivables accounts. |

| Services | Current costs, but not quantities, are tracked. You can sell these items individually or as part of a kit. Posting updates the Sales and Cash accounts. |

| Flat Fees | Current costs, but not quantities, are tracked. You can sell these items individually or as part of a kit. Posting updates the Sales account. |

Offset accounts appear on the Distributions Breakdown Register.

Posting from Purchase Order Processing affects the Cash or Accounts Payables accounts. Posting from Sales Order Processing affects the Sales, Cash, Cost of Good Sold, or Accounts Receivables accounts.

Miscellaneous charges include costs such as freight expense. You can't change this item type once it's assigned. Posting updates the Sales and Cash accounts.

Valuation methods

Valuation methods determine how the costs of inventory items are calculated. While you can have different valuation methods for different items or companies, we recommend that you talk to your tax accountant before changing the valuation method you currently use. The following table describes the valuation methods available and explains how each is used.

| Valuation method | Description |

|---|---|

| FIFO perpetual | Items purchased first are considered sold first (First In, First Out). Detailed information about the cost of all items is maintained, and the inventory is valued at its actual cost. The current cost for items is the cost of the item the last time it was purchased. |

| LIFO perpetual | Items purchased last are considered sold first (Last In, First Out). Detailed information about the cost of all items is maintained, and the inventory is valued at its actual cost. The current cost for items is the cost of the item the last time it was received. |

| Valuation method | Description |

| Moving average perpetual | The cost of items with the same item number is totaled and an average cost is assigned to the items. The average cost of an item is revalued throughout the period as you enter increase transactions for items. The average cost also is used as the current cost. The formula is: |

| FIFO periodic | Items purchased first are considered sold first (First In, First Out), and are valued at their standard cost. To update the standard cost, you can use the Inventory Year-End Closing window. At the end of the year, the standard cost can be adjusted to the current cost. |

| LIFO periodic | Items purchased last are considered sold first (Last In, First Out), and are valued at their standard cost. To update the standard cost, you can use the Inventory Year-End Closing window. At the end of the year, the fixed cost can be adjusted to the current cost, or the cost of the item the last time it was received. |

(Current units x current moving average cost) + (New units x purchase price) / (Current units + new units)

Cost variances—which can result with any of the valuation methods—are tracked in the General Ledger using the Inventory Variance account.

Standard and extended pricing

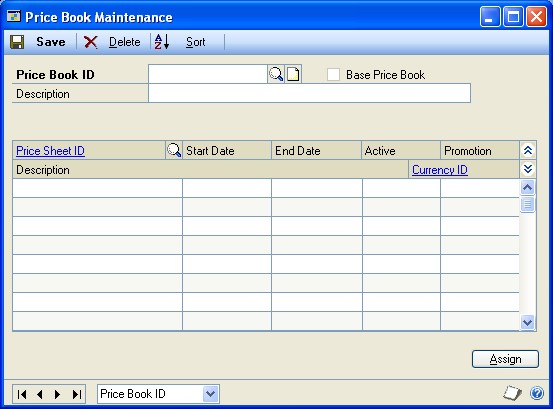

You have the option of using standard or extended pricing. Both pricing systems allow you to set up different pricing structures—price levels in standard pricing, or price sheets and price books in extended pricing. You can create different pricing for different currencies and different units of measure. Either system can be used to create pricing structures with quantity breaks. However, you must choose one pricing system and use it exclusively; you can't use both systems simultaneously.

Standard pricing

Standard pricing might be a better option for your company if any of the following conditions are true:

You're using Invoicing. (Extended pricing doesn't work with Invoicing.)

You want price lists to be updated automatically when the current cost or standard cost of an item changes.

You have a fairly simple pricing structure, and don't need additional tiers.

For more information about standard pricing structures, refer to Price methods and Standard pricing price structures.

Extended pricing

Extended pricing might be a better option for your company if any of the following conditions are true.

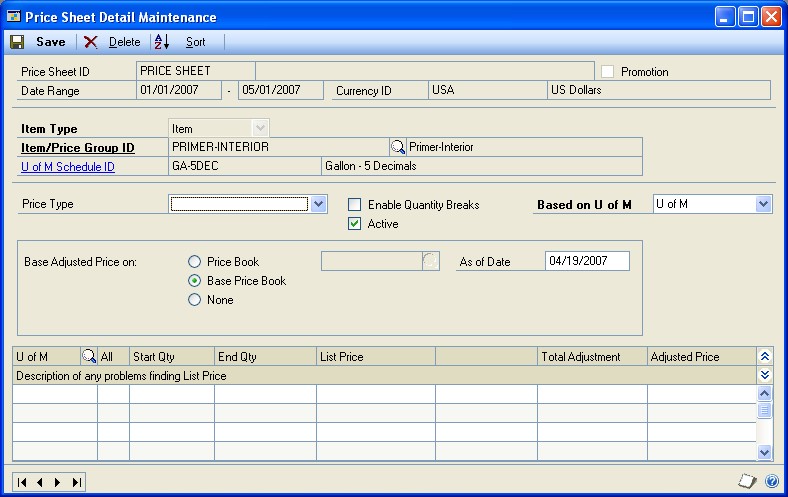

You want to use date-specific pricing.

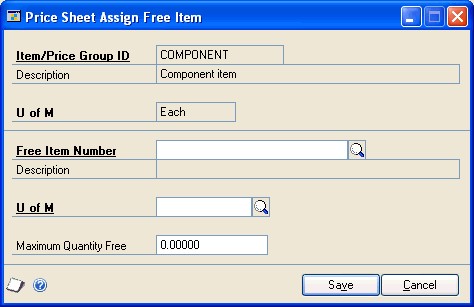

You want to create promotions for special pricing, such as value-off pricing or for "buy one, get one free" situations.

You have a complex pricing structure: you want to use more tiers or you want to apply multiple promotions simultaneously.

For more information about extended pricing, refer to Extended pricing terms and definitions and How prices are calculated.

Multiple bins

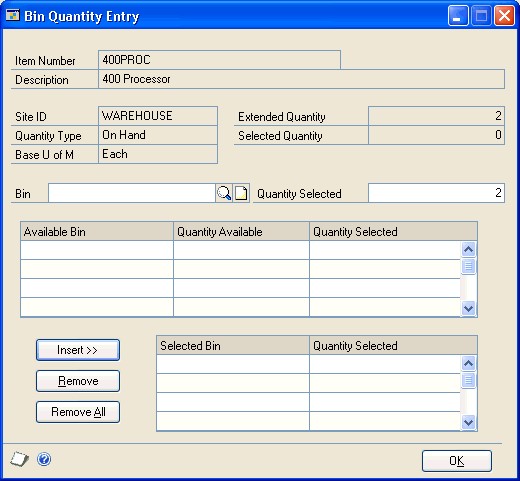

Use multiple bins to add a layer to item quantity tracking for items with the Sales Inventory or Discontinued item type. Besides tracking items within inventory sites, with multiple bins you can track item quantities in bins that reside within each site. Bin quantities are processed and displayed in the item's base unit of measure.

Note

You must register the multiple bins feature and enable it in Inventory Control before you can use it. Refer to Specifying preferences and default entries for more information about enabling multiple bins.

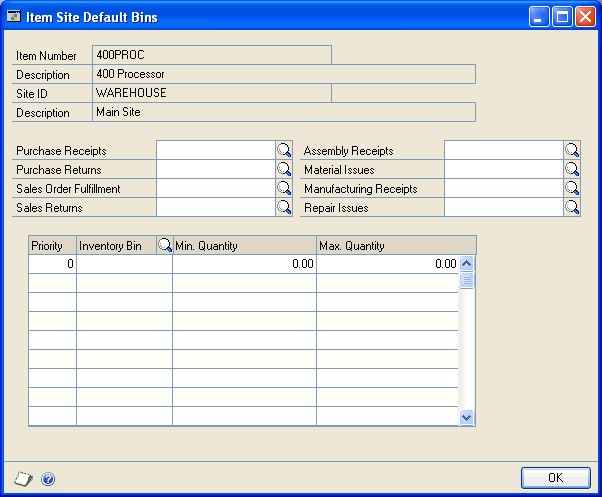

Default bins for transaction types at each site can be identified. For example, a default bin could be created for sales order transactions at your warehouse site. Default bins can also be identified for a particular item and transaction type at a site. If you always use Bin A when selling a certain item from your main site, for example, you can set up Bin A as the default sales order bin for the item at the main site.

When you enter a transaction, the default bin for the transaction type for the itemsite combination or the site is used automatically. In most cases, if there isn't a default bin for the item-site combination or the site, you can enter a bin.

Refer to the table for more information about when default bins are suggested and whether you can change them.

| Module or series | Default bin supplied? | Can you change it? |

|---|---|---|

| Bill of Materials | Yes | No |

| Inventory Control | No | You must specify the bin when you enter the transaction. |

| Invoicing | You can't use multiple bins if you're using Invoicing. | |

| Purchase Order Processing | Yes | Yes |

| Sales Order Processing | Yes | Yes |

| Field Services Series | Yes | Yes |

| Manufacturing Series | Yes | Yes |

Note

For information about how multiple bins are used in each module, refer to the documentation for the module.

You can transfer items from one bin to another. You can also remove bin records from a site or an item-site combination. You can select a range of bins to remove, and you can select a range of sites and items from which to remove bins. You'll be able to enter a reason code for each transfer so that you can identify reasons for the item movements.

For more information about multiple bins, refer to the following topics:

Preparing to use multiple bins

How bins affect transactions

Stock count overview

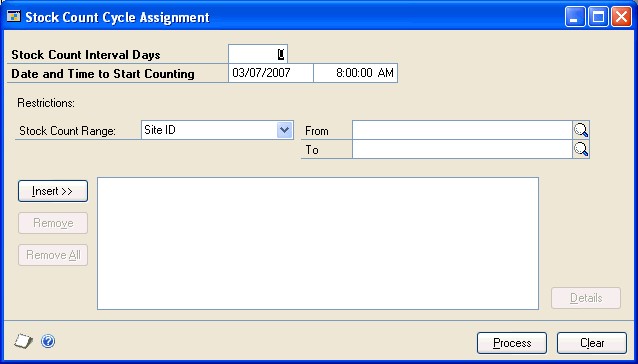

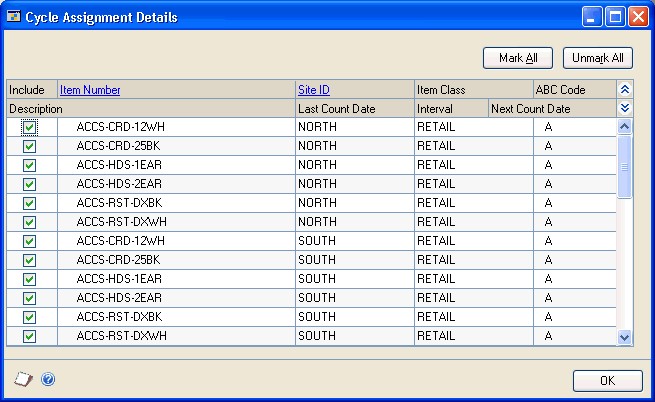

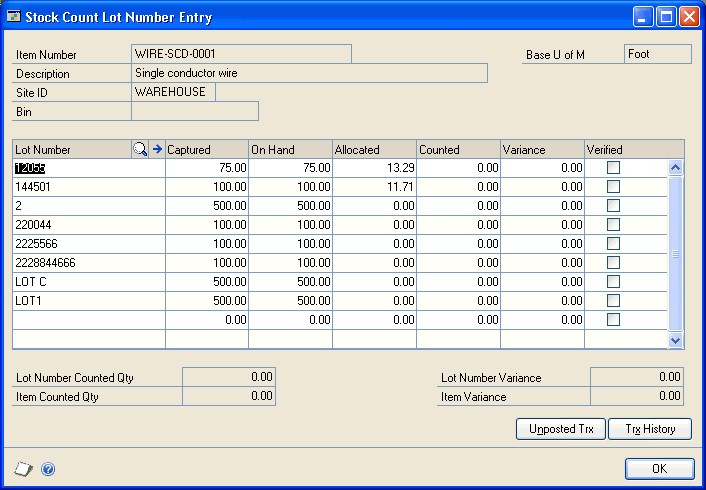

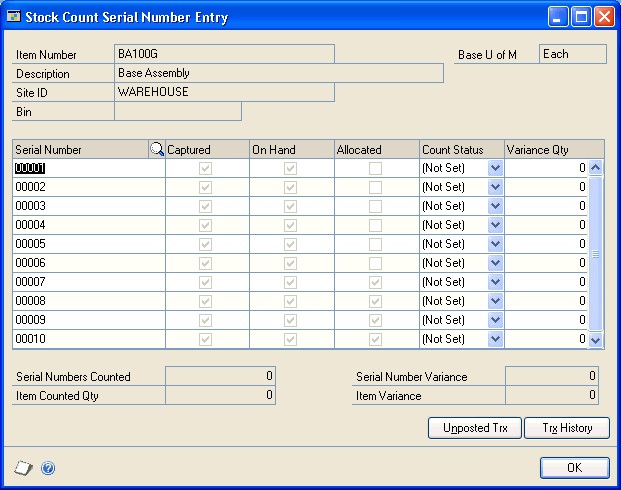

To help you monitor your inventory and the accuracy of your inventory records, you can use Inventory Control to complete stock counts, which include both cycle counts and physical inventory counts. Cycle counting is the practice of having inventory personnel count items on an on-going basis. If you want inventory personnel to complete some counts every day or every week, you'll probably want to use cycle counting. Physical inventory counts occur when all items are counted at the same time. Inventory Control's stock count system includes both cycle counts and physical inventory counts.

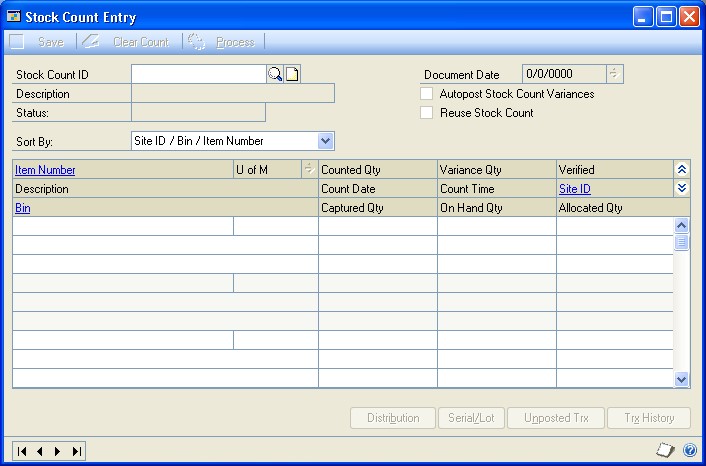

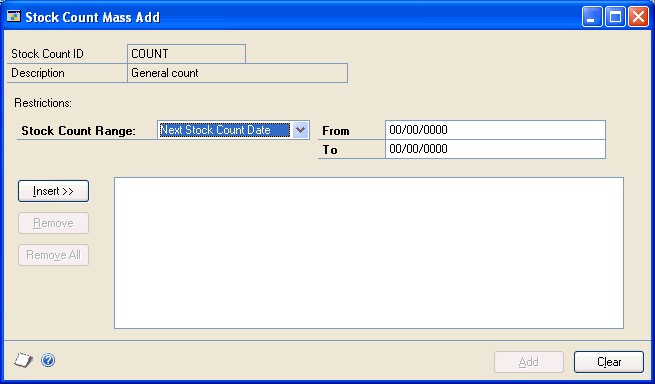

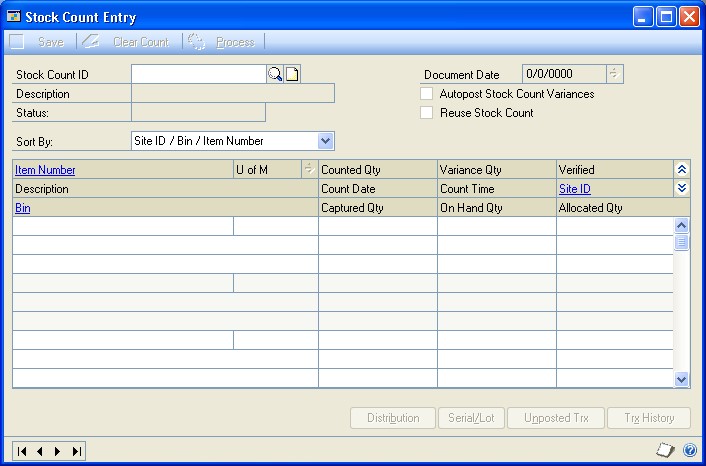

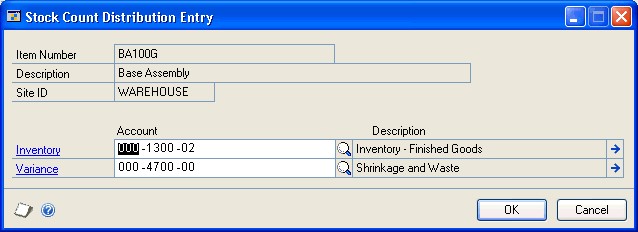

With Inventory Control, you can specify items to be counted in a stock count schedule. After the count is complete, you can enter the results. The counted quantities are compared with inventory record quantities. You can use variance transactions—if needed—to correct discrepancies. Later, you can compare the accuracy of different stock counts with the Accuracy Comparison report. The information on that report can help you spot inventory trends, which can be helpful in determining business practices.

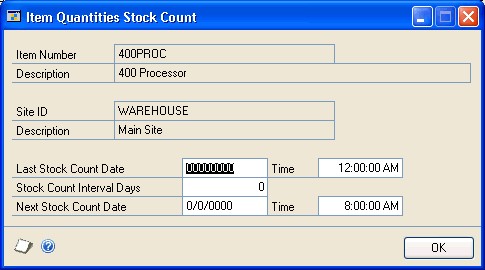

You can specify how frequently you want to count each item number at each site. For example, you might want to count critical items every 30 days, and you might want to count relatively unimportant items—such as supplies—much less frequently. You can specify a different count frequency—or "cycle"—for each item at each site.

Once you've specified a group of items with the same cycle frequency, Inventory Control divides the number of items to be counted over the cycle period. For example, if you have 100 item numbers to be counted every 10 days at a site, Inventory Control would schedule 10 items to be counted each day. This helps to minimize the impact of the stock counts on your inventory personnel.

Refer to these topics for more information about using stock counts and cycle counting.

Chapter 8, "Stock count calendar," explains how to create and modify a stock count calendar—the calendar the system will use to determine the days when a stock count might be done.

Chapter 18, "Count intervals," describes how you can specify a count interval for groups of items.

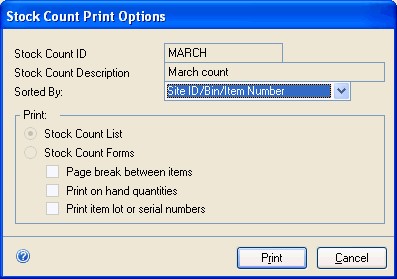

Chapter 22, "Stock count schedules," includes information about starting a stock count—specifying which item-site combinations should be included in the count, printing forms to record count information, and so on.

Chapter 23, "Stock count processing," contains information about entering the results of a stock count, working with default variance transactions, and generating the stock count accuracy report. Information about using the report also is included.

Chapter 2: Setup preparation

Inventory Control integrates with several other modules, so be sure you've completed the setup procedures for those modules before you begin setting up Inventory Control.

When you set up Inventory Control, you can open each setup window and enter information, or you can use the Setup Checklist window (Administration >> Setup >> Setup Checklist) to guide you through the setup process. See your System Setup Guide (Help >> Contents >> select Setting up the System) for more information about the Setup Checklist window.

The following information is discussed:

System Manager, General Ledger, and Payables Management setup

Multicurrency Management setup

System Manager, General Ledger, and Payables Management setup

Before you begin setting up Inventory Control, be sure you've completed setup procedures for the following items.

Company setup When you complete company setup tasks, be sure to set up the following information. For more information, refer to your System Setup instructions (Help >> Contents >> select Setting Up the System).

Company settings

Shipping methods

Payment terms

Credit cards

Fiscal periods

Account formats

Tax schedules

Bank information

Financial setup You also must set up certain cards related to your financial information. Be sure to set up accounts, currencies, and checkbooks. For more information, refer to your System Setup instructions (Help >> Contents >> select Setting Up the System) and General Ledger documentation.

Posting accounts

Checkbooks

Currencies

Unit accounts

Variable allocation accounts

Fixed allocation accounts

To track variances separately for inventoried items, you need to set up an Inventory Variance Account before setting up Inventory Control. Refer to the General Ledger documentation for more information about setting up accounts.

Posting setup You also must set up the following posting options. For more information, refer to your System Setup instructions (Help >> Contents >> select Setting Up the System).

Posting options

Posting accounts

Source document code information

Audit trail code information

Purchasing setup You must create vendor records. (Refer to your Payables Management documentation for more information.)

Sales setup If you're using extended pricing and want to set up special pricing for specific customers and prospects, you must create the customer or prospect records. (Refer to your Sales Order Processing documentation for more information.)

Multicurrency Management setup

If you're using Multicurrency Management, you can use Inventory Control to create separate pricing in each currency for each inventoried item. Before you can do this, however, you must complete these Multicurrency Management setup tasks:

Functional currency The functional currency for the organization—the currency your business will use to keep the bulk of its financial records—must be defined.

Other currencies Currencies must be assigned to the company before they can be assigned to the items of the company, so be sure you've assigned all currencies needed for price lists to the company. (Currencies other than a company's functional currency are originating currencies.)

Chapter 3: Preferences and default settings

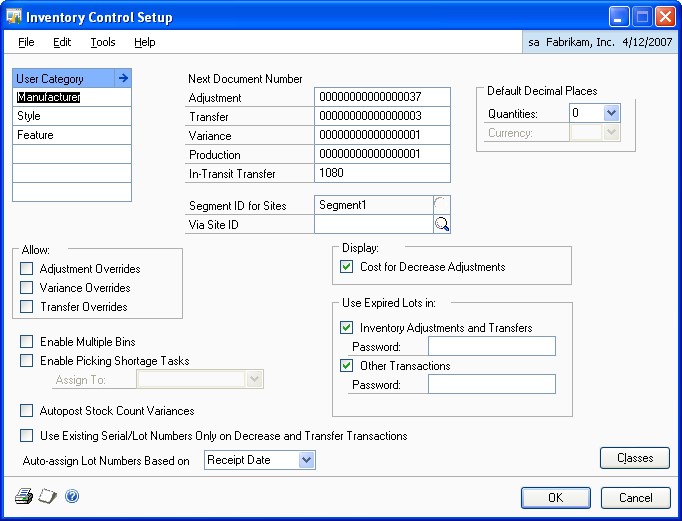

Inventory Control includes several options and default entries to control how certain processes will work in your inventory system. The preference and default settings in the Inventory Control Setup window will affect how information appears throughout Inventory Control. Use the Inventory Control Setup window to complete the following tasks:

Defining user categories, which you can use to organize inventoried items into broad groups.

Entering the starting document numbers for use in transaction entry.

Selecting the account segment to represent site information.

Specifying the default number of decimal places for item quantities and currency amount.

Specifying the types of transaction overrides—such as variance overrides—to be allowed.

Specifying if costs should be displayed for decrease transactions.

Specifying if stock count variance transactions should be posted automatically.

Specifying whether multiple bins should be enabled.

Specifying how to use lot numbers.

Specifying whether to create tasks in the Task List window when there is a picking ticket shortage.

Note

Most of these tasks are described in Specifying preferences and default entries. Refer to Defining a user category for more information about defining user categories and values.

The following information is discussed:

Specifying preferences and default entries

Preparing to use multiple bins

Handling existing quantities for multiple bins

Multiple bins and existing stock counts

Defining a user category

Specifying preferences and default entries

Use the Inventory Control Setup window to specify basic Inventory Control settings. You can set up user categories, specify the beginning document numbers for different transaction types, and set the default number of decimal places to be used when entering new item records.

Note

If you're starting to use multiple bins, it's best to enter registration keys for multiple bins, define the bins for each site, and assign default bins to items and sites before marking the option to enable multiple bins. Refer to Preparing to use multiple bins. If you already have item quantities in Microsoft Dynamics GP, you'll need to complete certain tasks so that those records are updated appropriately for using multiple bins. Refer to Handling existing quantities for multiple bins.

To specify preferences and default entries:

Open the Inventory Control Setup window. (Inventory >> Setup >> Inventory Control)

You can enter up to six user categories to classify related items.

User categories are user-defined item categories that provide a way for you to group your inventory and analyze trends in purchases and sales. Refer to Defining a user category.

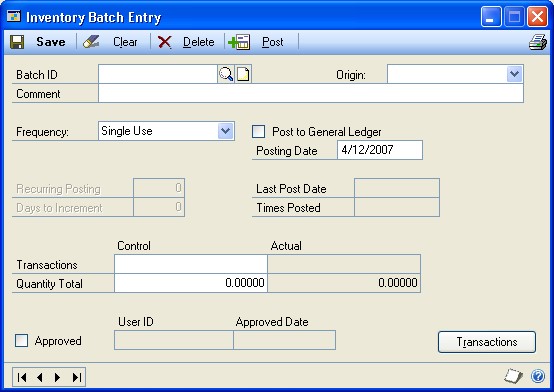

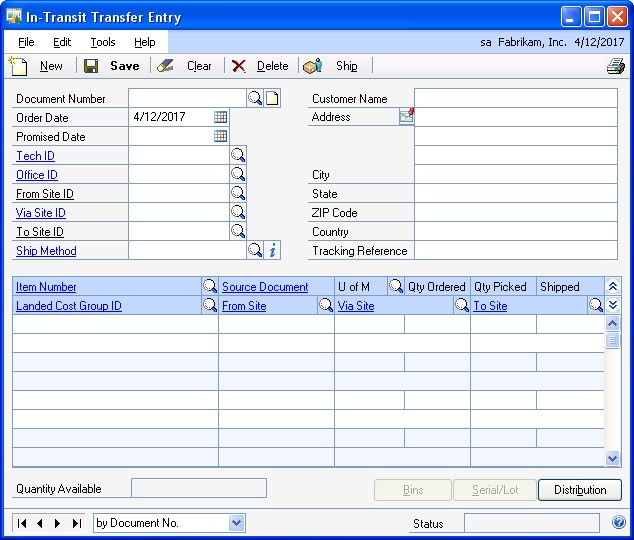

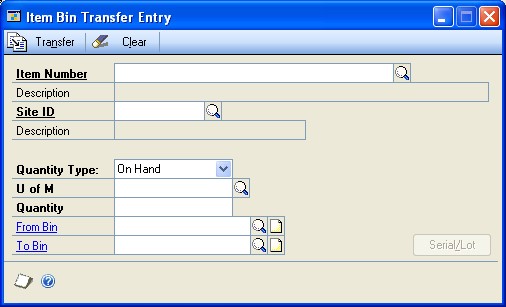

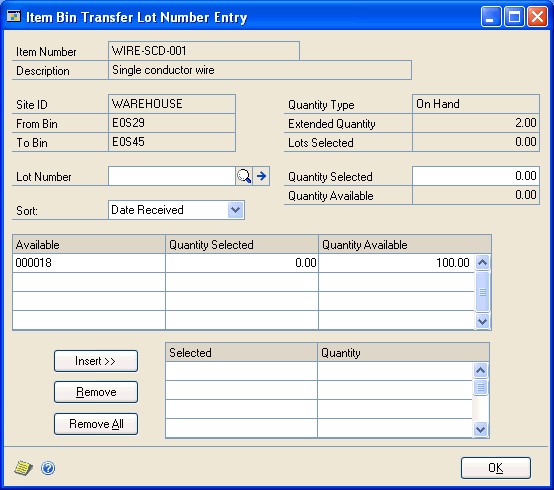

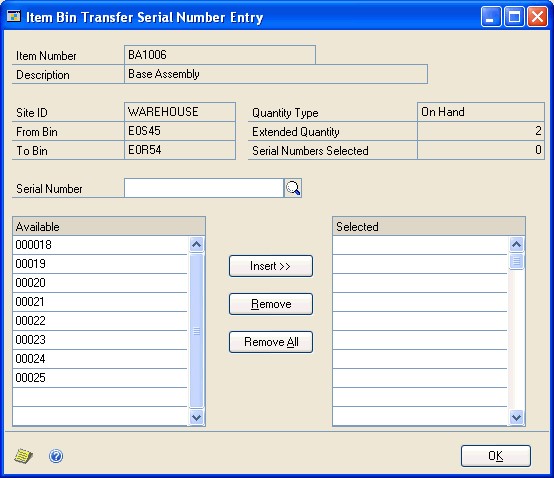

Enter the next document number for adjustment, transfer, variance, bin transfer, and in-transit transfer transactions. For more information about inventory transactions, refer to Inventory Control transactions

The document numbers you enter will be the next numbers assigned to adjustment, transfer, and variance documents. To ensure that enough document numbers will be available for future documents, the document numbers must end with a numeral that includes leading zeros—for example, ADJ0001. Each time you enter transactions, the default document number increases to the next available number. You can change the next document number, if needed, but the same document number can be posted only once.

The numbers you enter also determine the number of unique document numbers available. For example, if you enter ADJ0001, you can enter only 9,999 unique adjustment transactions.

In order to use document numbers for bin transfers, you must first select Enable Multiple Bins.

Enter or select the site ID that is the interim location for items that are being moved from one site to another using an in-transit transfer transaction. You can use the via site to ensure that the items aren't sold before the items reach their destination.

If you leave the Via Site ID field blank, you must enter a site ID when entering new in-transit transfer transactions.

Enter or select an account segment ID to represent sites.

The account segment ID corresponds to the accounts you set up in Account Segment Setup window to track items by site. Once you've entered this information and moved the pointer out of the field, you can't change it.

Enter or select the number of decimal places to use as a default number of places for item quantities when creating new item records.

If you're not using Multicurrency Management, enter or select the number of decimal places to use as a default number of places for displaying currency amounts associated with items. (If you're using Multicurrency Management, this field won't be available.)

Choose which override options to allow. If you allow overrides, you can allocate quantities that are greater than the quantity available.

To use multiple bins at each inventory site, mark Enable Multiple Bins. This option must be marked in order to use the next document number for bin transfers.

Note

If you're using stock counts, you should be aware of how marking this option will affect your existing stock count records. Refer to Multiple bins and existing stock counts for more information.

Marking this option will change Microsoft Dynamics GP processing so that bin information is required for transactions. Before you mark this option, you should complete several setup tasks related to multiple bins. Refer to Preparing to use multiple bins for more information.

Choose whether a task should be created if a picking ticket shortage is entered is found. After the shortage occurs in the Sales Order Fulfillment Entry window or the Manufacturing Component Transaction Entry window, a message will appear, and you will have the option to create a task for the quantity shortage.

You can use the task to create a stock count or to locate the missing quantities. You must enter a user ID to create tasks for picking ticket shortages.

Choose whether stock-count variances should be posted automatically.

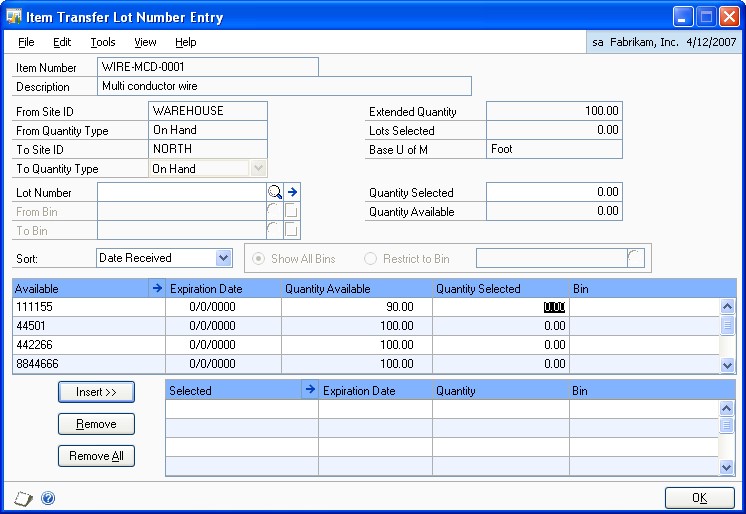

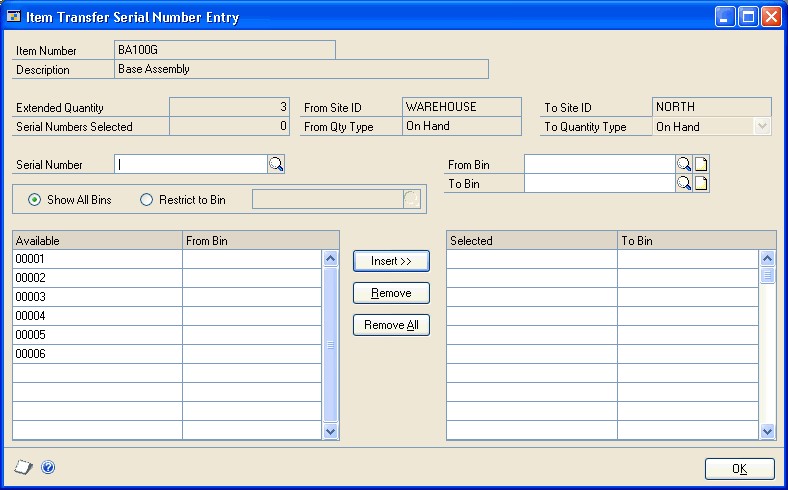

Choose whether to use only existing lot numbers and serial numbers on decrease and transfer transactions. By marking this option, you can't enter a new lot number or serial number when entering a decrease transaction or transfer transaction in Inventory Control, Microsoft Dynamics GP Bill of Materials, Sales Order Processing, or Invoicing.

Select to automatically assign lot numbers to transactions by receipt date or expiration date in Sales Order Processing, Microsoft Dynamics GP Bill of Materials, and Invoicing. To use the lot numbers nearing expiration first, select to assign lot numbers by expiration date.

Choose whether costs for decrease adjustment transactions should be displayed.

Choose whether to use expired lots when entering inventory adjustments and transfers. In the Password field, you can enter a password for this option if you want to limit the users who can use expired lots. If this option is not marked, expired lots can't be used when entering inventory adjustments and transfers.

Choose whether to use expired lots when entering transactions in Microsoft Dynamics GP Bill of Materials, Purchase Order Returns, Sales Order Processing, Invoicing, and Manufacturing. In the Password field, you can enter a password for this option if you want to limit the users who can use expired lots. If this option is not marked, expired lots can't be used when entering transactions in other modules.

Choose OK to save your changes.

When you've entered your preferences and default settings, you can verify your entries by choosing File >> Print to print the Inventory Module Setup Report. You also can print this report by choosing the print icon button in the window.

Preparing to use multiple bins

Before you begin to use multiple bins in transactions, you should complete several setup tasks. For example, you should create the bins at each site, and specify default bins for each site and for each item-site combination. You can complete these tasks as soon as you've entered registration keys for multiple bins. Refer to Multiple bins for more information about multiple bins.

Refer to the following topics for information about the tasks that should be completed after you've registered the multiple bins feature, but before you mark the option in the Inventory Control Setup window.

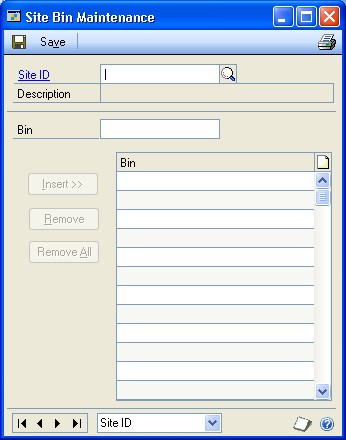

Entering bins for a site

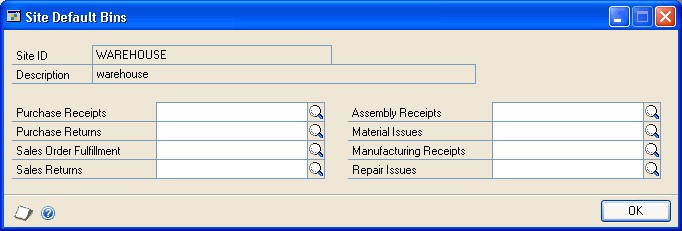

Specifying default bins for a site

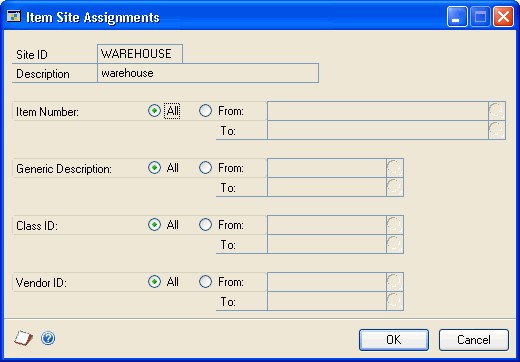

Specifying default bins for an item-site combination

Specifying preferences and default entries

Note

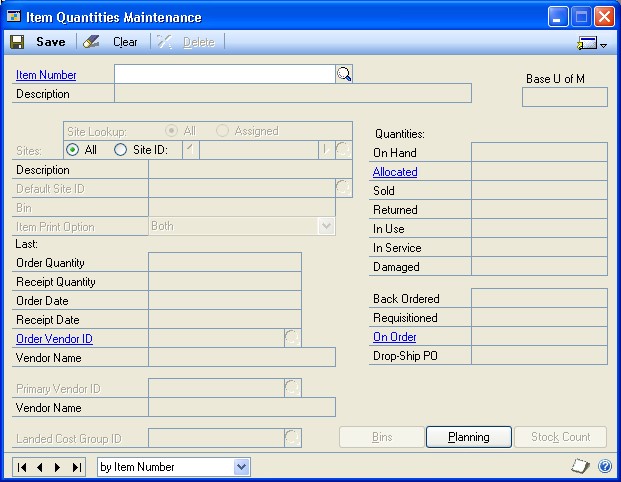

If you have existing inventory quantities, you also might want to enter a bin name in the Bin field in the Item Quantities Maintenance window for each item-site combination. The quantities for each item-site combination automatically will be put in this bin (from a software perspective) when you mark the option to enable multiple bins.

When you've completed those tasks, you can mark the option to enable multiple bins. An alert message will appear, telling you to reconcile inventory and to check links. These steps are required only if you have existing inventory quantities. For more information, refer to Handling existing quantities for multiple bins.

Handling existing quantities for multiple bins

An alert message appears when you mark the option to enable multiple bins, telling you to use the inventory setup checklist. The checklist will direct you to reconcile inventory and check links, among other things. You can complete those tasks immediately, or you can edit your pending (unposted) transactions first.

It's helpful to understand how Microsoft Dynamics GP changes and updates information for multiple bins.

Marking the Enable multiple bins option After you mark the option, bin information is required for any new transaction that's entered.

Reconciling inventory and sales documents When you reconcile inventory and sales documents, Microsoft Dynamics GP supplies bin information to unposted transactions. The bin that Microsoft Dynamics GP supplies for each unposted transaction is the default bin for the transaction type for the item-site combination or the site.

After you mark the option to enable multiple bins and before you reconcile inventory and check links, you can edit unposted transactions to add the bin information. You need to do this only if you want to use bins other than the default bins.

Refer to Modifying an unposted transaction for more information.

After you've edited the unposted transactions—or immediately after marking the option to enable multiple bins, if it's OK if the default bins are used for the transactions—you need to complete the steps described in the following table.

| Task | Reference |

|---|---|

| Reconcile sales documents | Refer to the Sales Order Processing documentation. |

| Reconcile inventory | Refer to Reconciling inventory records. |

| Check links | Refer to your System Administrator's Guide (Help >> Contents >> select System Administration), referencing the tables listed below. |

The System Administrator Guide includes information about how to check links. You'll need to check links for the following combinations of series and tables. Refer to the table for more information.

| Series | Logical tables | Required |

|---|---|---|

| Inventory | Item Master | For anyone using multiple bins who has existing inventory quantities |

| Inventory Transaction Work | ||

| Bill of Materials Transactions | Only if you use Bill of Materials | |

| Stock Count | Only if you use stock counts | |

| Sales | Sales Work | Only if you use Sales Order Processing |

| Purchasing | Purchasing Transactions | Only if you use Purchase Order Processing |

If any of these processes fail, contact technical support.

When you reconcile inventory for multiple bins, a bin automatically is created for each site that's already set up in Microsoft Dynamics GP, and all quantities of items at that site are put in that bin. If you've entered a bin name in the Item Quantities Maintenance window, that bin name is used; otherwise, a bin called AUTOCREATE automatically is created. For information about moving the quantities to their appropriate bin locations, refer to Transferring quantities from one bin to another.

When you reconcile sales documents, bin information is added to unposted sales transactions. The default bin used is the default bin for the transaction type for the item-site combination or for the site. If no default bin for the item-site combination or the site is available, the quantity fulfilled will be cleared and you'll need to use Sales Order Processing windows to fulfill the documents before they can be posted.

Multiple bins and existing stock counts

If you mark the option to Enable Multiple Bins in the Inventory Control Setup window, bin information also is required for each line in each stock count.

If possible, it's a good idea to finish processing any Started or Entered stock counts before you mark the option to use multiple bins. You also should post any variance transactions resulting from those stock counts.

Refer to the table for information about how stock count IDs are affected, depending on their status.

| Status | Effect of marking the Enable Multiple Bins option |

|---|---|

| Available | When you enter or select the stock count in the Stock Count Schedule window or the Stock Count Entry window, an alert message appears. If you choose to continue using the stock count, the bin information in the stock count will be cleared and you must enter valid bin information before you can start the stock count. If the status of the stock count was Started, it will be reset to Available. |

| Started | |

| Entered | When you enter or select the stock count in the Stock Count Entry window, an alert message appears, telling you that the stock count has been converted for use with multiple bins. Any bin information and any stock count results you've entered will be cleared. You must enter the necessary bin information before you can restart the stock count. |

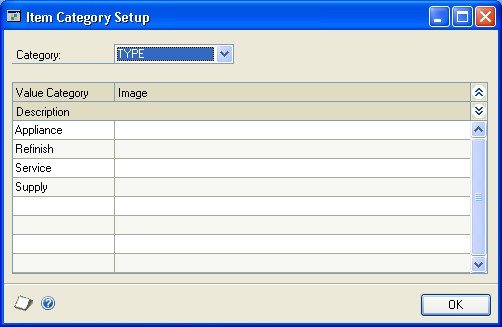

Defining a user category

Use the Inventory Control Setup window to create user categories—groups of item characteristics—and then use the Item Category Setup window to define values for each category. For example, you might create a user category called Storage if you have inventoried items that require special storage conditions. Then you could use the Item Category Setup window to create different values—such as Refrigeration or Hazardous—to assign to items that require special handling.

You can create as many as six user categories. Each category can include unlimited values.

To define a user category:

Open the Inventory Control Setup window. (Inventory >> Setup >> Inventory Control)

Enter a user category in the first blank user category field.

Choose the expansion button to open the Item Category Setup window.

Select the Category.

Enter values for the category in the scrolling window. You can enter a description of the value or a path to an image.

Your entries automatically are saved as they're entered in the scrolling window.

When you've finished entering information, choose OK.

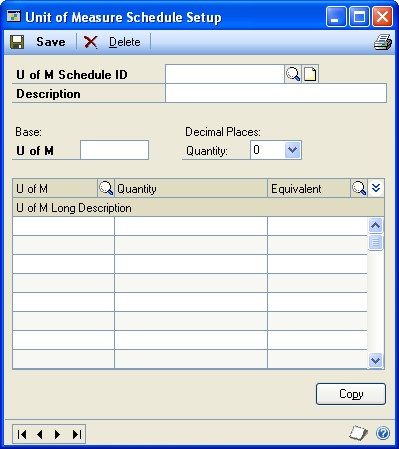

Chapter 4: Unit of measure schedules

To be able to purchase and sell the same inventoried item in different quantities, you can use unit of measure schedules. A unit of measure schedule is a sort of conversion table that helps you define the equivalent number of units.

For example, you might purchase light bulbs by the case, and then sell them individually. If you set up a unit of measure schedule for the light bulbs, you can accomplish this.

Every inventoried item must be assigned a unit of measure schedule, but an item can't be assigned more than one unit of measure schedule.

The following information is discussed:

Creating a unit of measure schedule

Copying a unit of measure schedule

Modifying a unit of measure schedule

Deleting a unit of measure schedule

Creating a unit of measure schedule

Use the Unit of Measure Schedule Setup window to define a unit of measure schedule. You must create at least one unit of measure schedule, because a unit of measure schedule must be assigned to every inventoried item.

To create a unit of measure schedule:

Open the Unit of Measure Schedule Setup window.

(Inventory >> Setup >> Unit of Measure Schedule)

Enter an identifier and a description for the unit of measure schedule.

Enter or select the number of the decimal places for the quantities you plan to enter on this unit of measure schedule.

Note

The number of decimal places for entering and displaying quantity information for the item and for the unit of measure must match. You might need to create several unit of measure schedules that are the same except for the number of decimal places displayed.

Tip

You can create one schedule and make copies of it. Refer to Copying a unit of measure schedule for more information.

Enter a base unit of measure. This should be the smallest unit available for the item. When you move out of the field, a base equivalency—an equivalency that states that the smallest unit is equal to itself—automatically will be created in the first line of the scrolling window.

Note

Even if you purchase and sell an item in only one unit of measure, you need to set up a unit of measure schedule with the base equivalency information.

Set up the quantities, equivalents, and descriptions for each unit of measure you plan to use, relative to the base unit of measure.

For example, if you're selling cans of soft drinks and your base unit of measure is "can," you could set up equivalents as follows:

Unit of measure Quantity Equivalent Can 1 Can Six-pack 6 Can 12-pack 12 Can Case 24 Can Case 4 Six-pack When you've finished defining all units of measure for a schedule, choose Save.

When you've entered all of your unit of measure schedules, you can verify your entries with a Unit of Measure List report.

Copying a unit of measure schedule

Use the Unit of Measure Schedule Setup window to copy an existing unit of measure schedule. This is especially helpful if you need to create several similar schedules that differ only in the number of quantity decimals.

To copy a unit of measure schedule:

Open the Unit of Measure Schedule Setup window.

(Inventory >> Setup >> Unit of Measure Schedule)

Enter a name for the new schedule.

Enter or select the number of quantity decimal places to include.

Choose Copy and select an existing unit of measure schedule. The schedule you select must track a number of quantity decimals that is the same or fewer than the new schedule you're creating.

Make any changes as needed.

When you've finished, choose Save.

Modifying a unit of measure schedule

You can make changes to a unit of measure schedule at any time, including adding, modifying, and deleting equivalencies. The following requirements apply to modifying a unit of measure schedule:

If you change the base equivalency, all standard pricing price lists are updated but you must check links for the Item Master table for the update to occur. Prices won't change. If an item is sold before you check links, the item will be sold at its original price—not the updated price.

If you change the base equivalency, all extended pricing price sheet information for the item is not updated. You must edit price sheet information.

If you change a unit of measure schedule while an affected price list is open, the Unit of Measure Schedule Audit Report automatically will be printed when you save the changes to the schedule. The report lists the items whose price lists couldn't be updated when the unit of measure schedule was changed. You should check links for the Item Master table.

Tip

Refer to your System Administrator's Guide (Help >> Contents >> select System Administration) for more information about checking links.

To modify a unit of measure schedule:

Open the Unit of Measure Schedule Setup window. (Inventory >> Setup >> Unit of Measure Schedule)

Enter or select a unit of measure schedule.

Make any changes as needed. You can add or delete rows by placing your pointer in the scrolling window, choosing the Edit menu and selecting Add Row or Delete Row.

Note

You can't delete the base equivalency (where you make the smallest unit of measure equal to itself) if other equivalencies are included in the scrolling window.*

When you've finished entering changes, choose Save.

Deleting a unit of measure schedule

Use the Unit of Measure Schedule Setup window to delete a unit of measure schedule. This might affect other records, such as price lists based on the unit of measure. The following requirements apply when you're deleting a unit of measure schedule.

If you delete a unit of measure in a schedule, that unit of measure will be removed from any existing price lists or price sheets.

You must remove the unit of measure schedule from all items and item classes before you can delete the unit of measure schedule.

To delete a unit of measure schedule:

Open the Unit of Measure Schedule Setup window.

(Inventory >> Setup >> Unit of Measure Schedule)

Enter or select a unit of measure schedule.

Choose Delete. An alert message appears, asking if you're sure you want to delete the schedule. Choose Yes.

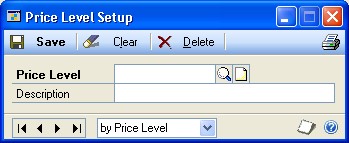

Chapter 5: Standard pricing

If you're using standard pricing, you can define price levels and price groups for use with price lists. A price level is a pricing tier that can be assigned to items, customers, and prospects. For example, you might create a Wholesale price level and a Retail price level—and then assign the Wholesale price level to certain customers.

Note

If you're using extended pricing, you don't need to complete these tasks, but you will need to enable extended pricing. Refer to the Sales Order Processing documentation for more information about marking the option to enable extended pricing, and refer to Chapter 12, "Extended pricing," for more information about setting up extending pricing.

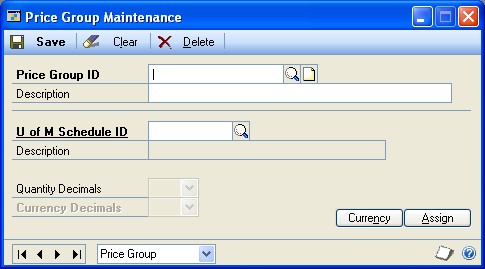

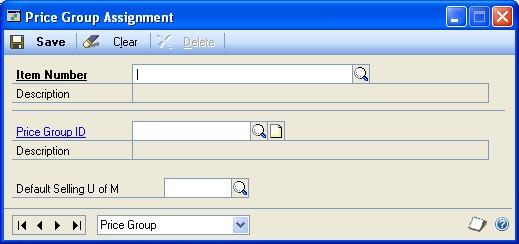

Price groups are identifiers that you can assign to items that have similar pricing structures. You can use price groups to specify the items to be included when you update price lists. For example, if you have several items that are identical except for their color, you might assign them all to the same price group. Later, you can use a price list wizard to update the price lists for all those items at once. Price groups also are an available option for some reports—you can choose to generate a report based on items that share a certain price group.

You don't need detailed pricing information to complete these pricing setup procedures—creating a price level or a price group involves creating the identifiers and entering brief descriptions of each price level or group.

Refer to Standard pricing price structures for more information about how you can combine pricing setup options to create different pricing structures.

The following information is discussed:

Creating a price level

Deleting a price level

Creating a price group

Deleting a price group

Creating a price level

Use the Price Level Setup window to create price levels. If you're going to use price lists, you must create at least one price level. Each price list must include at least one price level.

You don't need to complete this task if you're using extended pricing.

To create a price level:

Open the Price Level Setup window. (Inventory >> Setup >> Price Level)

Enter an identifier—such as Retail or Wholesale—and a description for the price level.

Choose Save.

If you're using Inventory Control with either Sales Order Processing or Invoicing, you can repeat steps 2 and 3 to create additional price levels. (You can't create more price levels if you're not using one of those modules.)

Deleting a price level

Use the Price Level Setup window to complete this procedure.

To delete a price level:

Open the Price Level Setup window. (Inventory >> Setup >> Price Level)

Enter or select a price level.

Choose Delete. An alert message appears, asking if you're sure you want to delete the record. Choose Delete.

Creating a price group

If you have several items that will have very similar price lists, you can group those items by creating a price group and then assigning the items to the price group. You can create as many price groups as you like. Price groups are optional.

Note

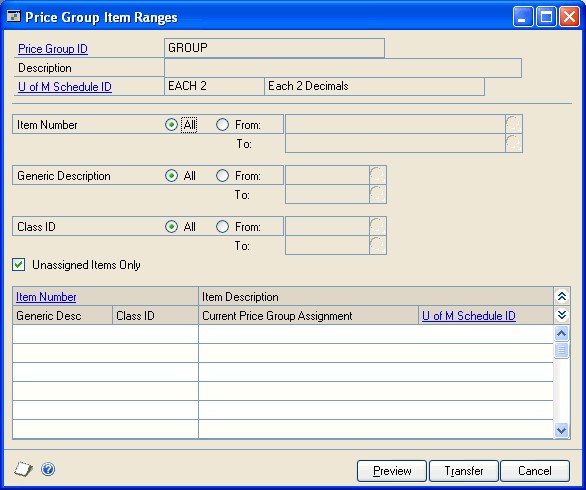

The price groups that are created with this procedure aren't the price groups used with extended pricing. If you're using extended pricing, refer to Creating and editing price groups.

Use the Price Group Setup window to complete this procedure.

To create a price group:

Open the Price Group Setup window. (Inventory >> Setup >> Price Group)

Enter an identifier and description for the price group.

Choose Save.

Deleting a price group

Use the Price Group Setup window to delete a price group, if needed. You can't delete a price group if it's assigned to any items or item classes.

To delete a price group:

Open the Price Group Setup window. (Inventory >> Setup >> Price Group)

Enter or select a price group.

Choose Delete. An alert message appears, asking if you're sure you want to delete the price group. Choose Delete.

Chapter 6: Lot category setup

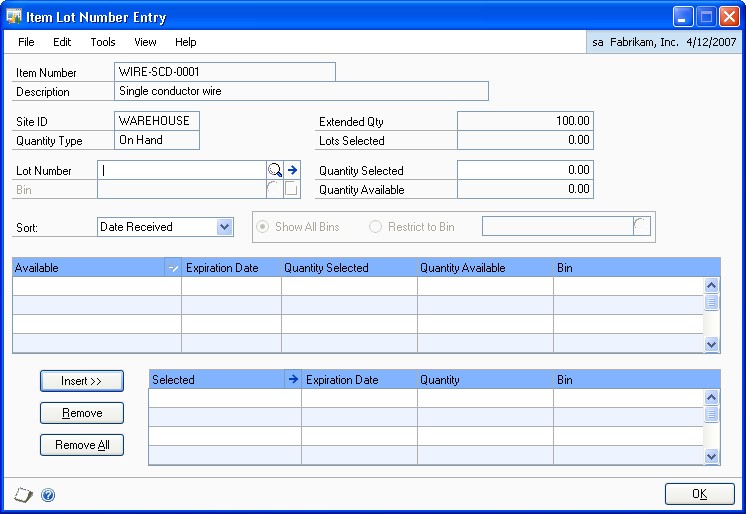

If your organization tracks items by lots, you can use lot categories to group lotnumbered items by shared characteristics. For example, items such as fabrics, carpets, and wallpaper are often assigned to lots, so that all items produced with a certain ink or dye can be tracked together. You also can create lot categories for tracking items to be used by or sold by a particular date, such as pharmaceuticals or cosmetics.

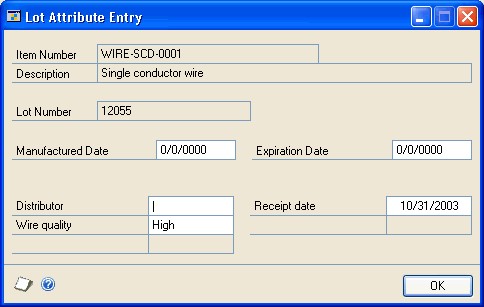

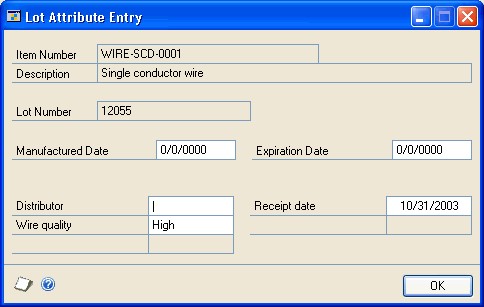

Once you've decided on the type of lot category you want to create, you can enter lot attributes for the category. Lot attributes are used when you enter an increase adjustment to further identify the lot-numbered item you've received. Tracking items by lot attribute is valuable if, for example, you've sold carpeting with specific dye and date attributes. If a customer who purchased carpeting with these attributes needs to purchase additional quantities, you'll be able to decrease quantities from the same lot category and ensure that the customer receives an identical product. If you are using sales fulfillment workflow, you can use the date attributes in the Lot Category Setup window to assign minimum shelf life attributes for an item. For more information, see Minimum shelf life

You can create an item record for a lot-number–tracked item without assigning a lot category to the item. If you don't assign a category, however, you won't be able to track the item by the attributes of the lot.

The following information is discussed:

Minimum shelf life

Creating a lot category

Modifying a lot category

Deleting a lot category

Minimum shelf life

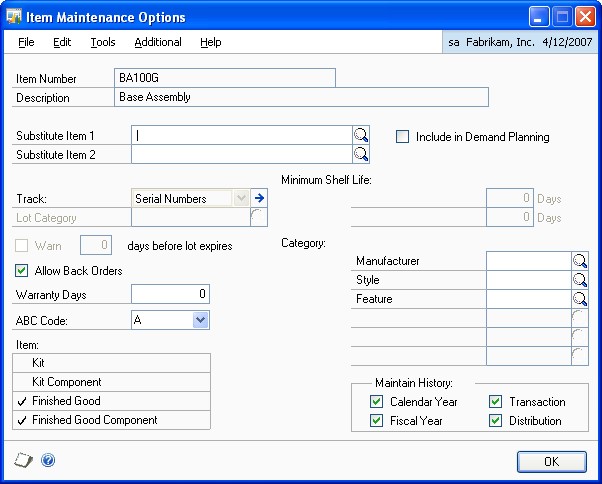

If you are using sales fulfillment workflow, you can use the Date 1 and Date 2 fields in the Lot Category Setup window to assign minimum shelf life attributes for an item. For example, you can enter Use By, Sell By, or Display Until as date attributes for an item. (You can enter an expiration date for an item in the Lot Attribute Entry window.) The attributes you enter will be displayed in the Item Maintenance Options window, where you can enter the number of days that you can use, sell, or display the item. The number of days you enter is used to determine whether or not the item meets the minimum shelf life when receiving the item in the Receivings Transaction Entry window.

For example, you need to ensure that the inventory you receive will not expire before it can be sold by your company. You enter Sell By as one of the date attributes for a lot category. Then, you enter the minimum number of days that it will take to sell the item in the Item Maintenance Options window. When the item is received, user date is subtracted from the Sell By date entered in the Lot Attribute Entry window to determine whether or not the item meets the minimum shelf life. If the difference between the Sell By date and the user date is less than the number of days entered in the Item Maintenance Options window, a message will be displayed indicating that the item received has less than the minimum acceptable shelf life.

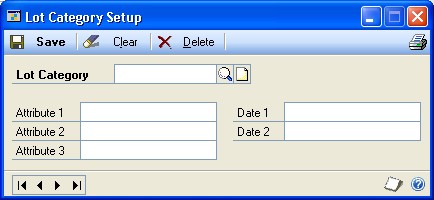

Creating a lot category

Use the Lot Category Setup window to create a lot category you can use to track the attributes of similar items.

If you are using sales fulfillment workflow, you can use the Date 1 and Date 2 fields to assign minimum shelf life attributes for an item. For example, you can enter Use By, Sell By, or Display Until as date attributes for the item's shelf life. The attributes you enter will be displayed in the Item Maintenance Options window. Refer to Minimum shelf life for more information.

To create a lot category:

Open the Lot Category window. (Inventory >> Setup >> Lot Category)

Enter a name or number for the lot category.

Assign up to five attributes, including as many as three alphanumeric and two date attributes. The attributes appear as labels in the Lot Attribute Entry window.

If you are using sales fulfillment workflow, you can use the date attributes to track the shelf life of an item. For more information, see Minimum shelf life

Save the lot category.

When you have entered all your lot categories, you can verify your entries with a Lot Category List.

Modifying a lot category

Use the Lot Category Setup window to change the names assigned to lot attributes.

When you change a lot attribute name, any information you've entered won't change or be removed—only the label will change.

To modify a lot category:

Open the Lot Category window. (Inventory >> Setup >> Lot Category)

Enter or select a lot category.

Make changes to the lot attribute names as needed.

When you've finished making changes, choose Save. You can verify your entries with a Lot Category List. For information about printing this and other setup reports, see Help >> Index, and search for Inventory Setup Reports window.

Deleting a lot category

Use the Lot Category Setup window to delete a lot category.

To delete a lot category:

Open the Lot Category window. (Inventory >> Setup >> Lot Category)

Enter or select a lot category.

Choose Delete. An alert message appears, asking if you're sure you want to delete the lot category. Choose Delete.

Chapter 7: Item classes

You can use item classes to group items according to common characteristics. If you define a class and then assign items to it, default information about the items will appear, making it quicker and easier to define new items. You also can use item classes to make changes to many items at once—you change the item class information and then "roll down" the changes to items that belong to the class. Item classes also are a common sorting option on reports.

The following information is discussed:

Relationship of item class to item record

Creating an item class

Assigning a currency to an item class

Specifying default accounts for an item class

Modifying an item class

Effects of changing item class information

Controlling the effects of item class changes

Removing a currency from an item class

Deleting an item class

Relationship of item class to item record

Before creating item classes, it's important to have an understanding of what your items are, and how they relate to your business. You can create item classes for groups of items that share certain characteristics such as valuation method or price group.

Using item classes can be helpful in these instances:

Entering new records When you create an item class, you can specify certain default settings and preferences for the items in the class: the number of decimal places for tracking quantities or currencies, the item type, and so on. Later, when you add an item record, you can select the appropriate item class—and the class information will be added to the item record. This can make data entry faster and more accurate.

Updating items in a class You also can use item classes to update several item records at once. If you change item class information and choose Save, an alert message will appear, asking if you want to "roll down" the changes to all items in the class. If you choose to do this, the change you made to the item class will be reflected in the records of the items that belong to the item class.

Refer to Controlling the effects of item class changes for more information about controlling the effects of item class changes.

Generating reports Item classes are one of the most common report restrictions available in Microsoft Dynamics GP.

Creating an item class

Use the Item Class Setup window to create item classes. Creating item classes is optional, but assigning items to a class gives you a way to organize your item records, sort information, and print reports.

To create an item class:

Open the Item Class Setup window. (Inventory >> Setup >> Item Class)

Enter an identifier and description for the item class.

Important

We recommend that you set up your first class with the most common entries and mark this class as your default class. If you mark the Default option, the information you define for this class automatically appears as the default for every subsequent class you create. This makes data entry faster if similar entries are required in many classes. You can save only one default item class.

Select an item type. Refer to Item types for more information.

Select a valuation method for how costs are tracked and how quantities are entered and removed from inventory. Refer to Valuation methods for more information.

Tip

If you enter the wrong valuation method, you must use the Change Valuation Methods window to change it. Refer to Changing valuation methods for more information.

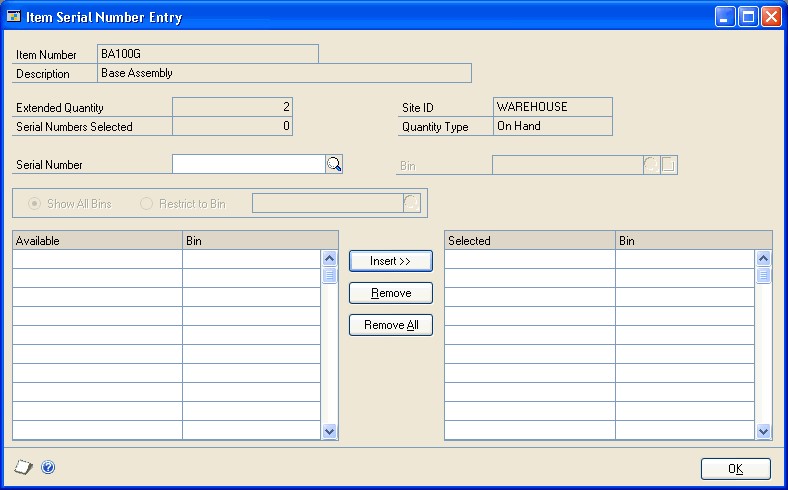

Specify if serial or lot numbers will be tracked for items in this class. The tracking option is available only for sales inventory or discontinued items.

Tip

If you choose to track items by lot number, you can enter or select a lot category—a set of item attributes you want to track for the lot. Refer to Chapter 6, "Lot category setup," for more information about defining lot categories. Refer to Entering lot attribute information for more information about entering lot category values.

If you selected to track lot numbers, you can select to be warned before a lot number expires. After marking the Warn option, you can enter the number of days you want to be warned before the lot number expires. You won't receive a warning message if you leave the days before lot expires field blank.

If you marked the Lot Due to Expire reminder in the Reminder Preferences window, the number of days you enter is used when generating the reminder that a lot is nearing its expiration date.

Specify how the items in this class will be taxed. If you choose Taxable, choose a Tax Schedule ID.

Tip

Refer to your System Setup instructions (Help >> Contents >> select Setting Up the System) for more information about tax schedules.*

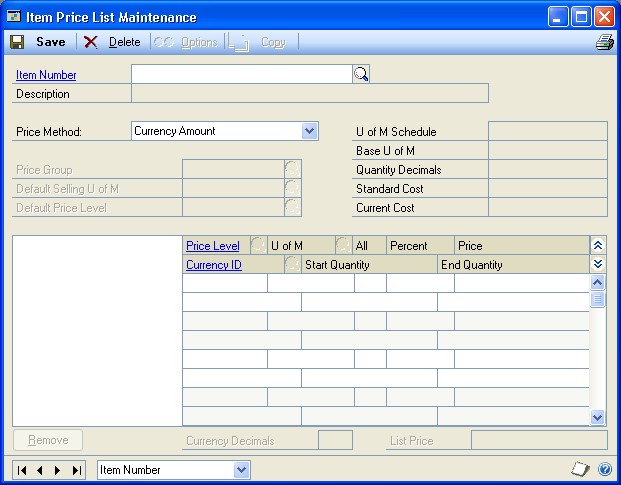

If you're using standard pricing, enter or select a price method for the item class. Refer to Price methods for more information.

If you're using extended pricing, the price method isn't used.

Specify if back orders will be allowed in the Sales Order Processing module for items in this class.

If the item class will be for sales inventory or discontinued items, and if the Valuation Method is LIFO Perpetual, FIFO Perpetual, or Average Perpetual, you can specify whether purchase receipts for the item should be revalued when cost variances exceed certain levels. Mark Revalue Inventory for Cost Variance if you want this to occur.

If you mark Revalue Inventory for Cost Variance, enter a Tolerance Percentage. The tolerance percentage determines how large a cost variance must be— greater or less than the shipment receipt amount—before the purchase receipt is revalued. Refer to Cost variance tolerances for more information.

If the item class will be for sales inventory or discontinued items, you can specify quantity tolerances for shortages and overages for the quantity ordered when receiving against a standard or blanket purchase order.

- Shortage Mark Shortage and then enter the percentage to use when the quantity received is less than the quantity ordered. If the difference between the quantity received and quantity ordered falls within the quantity tolerance percentage, the difference between the quantities is canceled and the status of a line item is automatically changed to change order, received, or closed. The status of the line item depends on whether or not the line item has been invoiced.

- Overage Mark Overage and then enter the percentage to use when the quantity received is more than the quantity ordered. If the quantity received is over the overage tolerance, you will receive a message that you can't enter a quantity greater than the combined total of the Remaining to Receive quantity and the overage tolerance set up for the item.

Mark the history types to keep for this item class.

You must keep transaction history to print the Transaction History Report or to print details for the Historical Stock Status Report. You must keep distribution history to print the Distribution History Report. Both transaction and distribution history are kept automatically if you specify at the system level that you want to reprint posting journals. Refer to your System Administrator's Guide (Help >> Contents >> select System Administration) for more information.

Enter or select decimal places for quantities and currencies.

If you're using Multicurrency Management, the Currency Decimals field isn't available because the number of currency decimals will vary from one currency to another. Refer to Assigning a currency to an item class for more information.

Enter or select a unit of measure schedule and price group. The number of decimals used to track quantity information for the item and for the unit of measure schedule must be the same.

If you're using standard pricing, enter the price level that you use most often when selling items in this class. The price level you select should be one that will be in the price list of each item in the class.

If you're using Sales Order Processing and standard pricing, this price level will be the default entry if you enter a sales transaction for a customer that has no assigned price level.

Enter values for user categories, if needed. Refer to Defining a user category for more information about user categories.

If you're tracking Intrastat statistics, enter or select a tax commodity code and a country or region of origin.

These fields are available only if you've marked the Enable Intrastat Tracking option in the Company Setup Options window.

Choose Currency to open the Item Class Currency Setup window, where you can assign a currency to an item class, if you're using Multicurrency Management. Refer to Assigning a currency to an item class for more information.

Choose Accounts to open the Item Class Accounts Setup window, where you can specify default posting accounts for items in the class. Refer to Specifying default accounts for an item class for more information.

Choose Save.

When you've entered all class records, you can verify your entries with an Item Class List report.

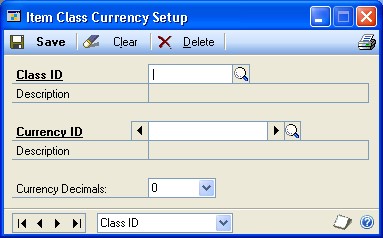

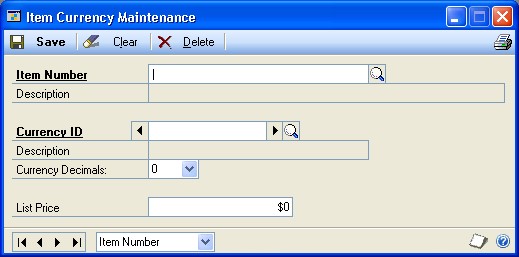

Assigning a currency to an item class

If you're using Multicurrency Management, use the Item Class Currency Setup window to assign currencies to item classes. You must assign a currency to an item to be able to create a price list in that currency for the item, or to use the item in Sales Order Processing or Purchase Order Processing.

Before you begin this procedure, you must set up your currencies in Multicurrency Management.

To assign a currency to an item class:

Open the Item Class Currency Setup window. (Inventory >> Setup >> Item Class Currency)

Enter or select a class ID.

Enter or select a currency ID.

Enter the number of currency decimals. You can change the number of currency decimals at any time.

Choose Save.

Repeat steps 3 through 5 to assign multiple currencies to the item class. You can assign as many currencies to an item class as you like.

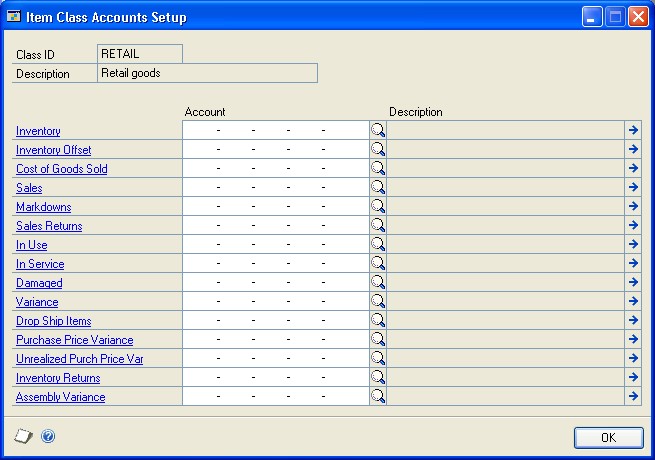

Specifying default accounts for an item class

Use the Item Class Accounts Setup window to specify default posting accounts for an item class.

To specify default accounts for an item class:

Open the Item Class Setup window. (Inventory >> Setup >> Item Class)

Enter or select an item class.

Choose Accounts to open the Item Class Accounts Setup window.

Enter or select the account numbers to be used for items in the class.

Later, when you create individual item records, you can accept or change the default posting account selections.

When you've finished selecting accounts, choose OK.

Modifying an item class

Use the Item Class Setup window to change item class information. When you change item class information, you might have the option to "roll down" your changes to the items that belong to the item class. Refer to Effects of changing item class information for information about what changes can be rolled down. Refer to Controlling the effects of item class changes for information about controlling the effects of item class changes.

To modify an item class:

Open the Item Class Setup window. (Inventory >> Setup >> Item Class)

Enter or select an item class.

Make changes as needed.

Choose Save.

Depending on the changes you've made, an alert message might appear, asking if you want to roll down the changes to all items in the class. Refer to Effects of changing item class information and Controlling the effects of item class changes for more information.

Effects of changing item class information

Some changes to item class information can be "rolled down" to items that have already been assigned to the item class. For example, if your company begins selling items to customers in a new currency and you assign that currency to the item class, you can choose to roll down the change, so the currency automatically is added to all items in the class.

Some changes to item class information, however, cannot be rolled down. Changes that cannot be rolled down include:

Number of decimal places for currency or quantity information

Valuation method

Price method, if you're using standard pricing

Unit of measure schedule

Some changes to item class information can be rolled down only in certain situations. These changes include:

Item types If you're changing the item type for an item class, the change can be rolled down only if you're changing the item type from Sales Inventory to Discontinued.

Track option If you're changing the lot- or serial-number tracking options for an item class, the change can be rolled down only to those items that have zero quantity in stock.

Default price level If you're using standard pricing and you're changing the default price level for an item, the change can be rolled down only to those items that already include the price level in their price lists.

Revaluing inventory and tolerance percentage If you're marking or clearing the Revalue Inventory for Cost Variance option, the change will be rolled down only to Sales Inventory or Discontinued items that have LIFO perpetual, FIFO perpetual, or average perpetual valuation methods. If you change the tolerance percentage for a class and choose to roll down the change, the percentage will be changed only for those items that have the Revalue Inventory for Cost Variance option marked.

If you make a change to an item class and the change is not rolled down, only new item records assigned to the item class will reflect the new information.

Controlling the effects of item class changes

When you create an item class, the options and selections you specify for the item class are inherited by any new items that are created and assigned to the class. Some changes that you might make to an item class can be rolled down to the items assigned to the class—other changes are reflected only in new item records assigned to the class. Refer to Effects of changing item class information for more information about what item class changes can be rolled down to items.

When you change an item record, carefully consider the relationship of the item to its item class. If you change an item that is assigned to a class, then change the information for the class and roll down those changes, the changes to the item record will be removed—and the item information will match the class information.

If you need to roll down item class changes Clear the class ID from any item record that shouldn't be updated when the class information changes.

If you don't need to roll down item class changes Use classes as a starting point for creating item records. Rather than rolling down changes to all items in the class, use updated item classes only to base new item records on.

Removing a currency from an item class

Use the Item Class Currency Setup window to remove a currency from an item class.

To remove a currency from an item class:

Open the Item Class Currency Setup window. (Inventory >> Setup >> Item Class Currency)

Enter or select a class ID.

Enter or select the currency to be removed.

Choose Delete. An alert message appears, asking if you're sure you want to delete the currency from the item class. Choose Yes, then close the window.

Deleting an item class

If an item class has become obsolete, you can delete it from Inventory Control. Because item classes are used only to make maintenance easier and faster, existing item records aren't affected when you delete the class. You can delete an item class at any time.

To delete an item class:

- Open the Item Class Setup window.

(Inventory >> Setup >> Item Class)

Enter or select the class you want to delete.

Choose Delete. An alert message appears, asking if you're sure you want to delete the class. Choose Yes.

Chapter 8: Stock count calendar

A stock count calendar identifies the days when a stock count can be performed. Days when counts can be performed are called up days; days when counts can't be performed are called down days. For example, you might choose to designate all Saturdays and Sundays as down days. You also can designate other days—such as company holidays—to be down days.

The stock count calendar serves these functions.

- First, the stock count calendar is used to determine the next suggested count date for each item-site (or, if you're using multiple bins, item-site-bin) combination. For example, if you define an item on June 1 and specify that it should be counted every 30 days, you're actually specifying that it should be counted every 30 up days. So, if you've specified down days within the month of June, the first suggested count date for the item at the site might be well into July.

Refer to How stock count dates are calculated for more information.

- Second, when you use cycle counting, the suggested count dates are spread over the length of the cycle. For example, if you specify 300 items you want counted at a specific site every 30 days, stock count dates for the items will be calculated so that you're counting quantities for 10 item numbers each of the 30 up days in the cycle. (If the number of items can't be evenly divided by the number of days in the cycle, the remainder is spread as evenly as possible over the cycle.)

For more information about cycle-counting, refer to Chapter 18, "Count intervals."

The following information is discussed:

Setting up a stock count calendar

Changing stock count calendar settings

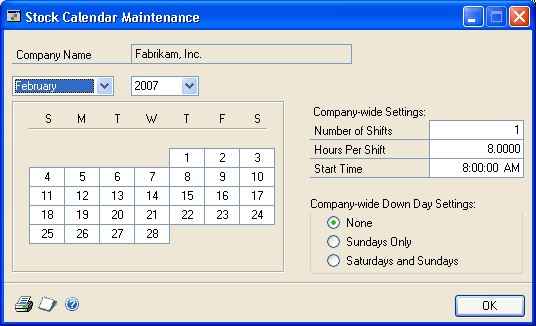

Setting up a stock count calendar

Use the Stock Calendar Maintenance window to set up a stock count calendar.

To set up a stock count calendar:

Open the Stock Calendar Maintenance window.

(Inventory >> Setup >> Stock Calendar)

The window opens with the current month and year displayed.

Enter the number of shifts that can complete stock counts, and the number of hours per shift that are available for the stock count tasks. Enter the start time for the first shift.

The number of shifts, number of hours per shift, and the start times for the shifts are optional—the fields are informational only.

Select the companywide days off. For example, if your company does not have a weekend shift, you would select Saturdays and Sundays.

If your company is usually closed on Saturdays and Sundays but you set aside one day each year or quarter to do the stock counts, you can select the Saturdays and Sundays option and then choose the date of the stock count.

To select additional company holidays or other down days, select the month, then select the day. (To change the day back to the original setting, select the day again.)

Days that appear black with white text are designated down days.

Days that appear white with black text are designated up days (days when counts can be performed).

Choose File >> Print to print the Stock Count Calendar List.

This report shows you which days are designated as companywide down days. You also can print the report from the Inventory Setup Reports window. Choose Inventory >> Reports >> Setup to open that window.

Choose OK to save your changes and close the window.

Changing stock count calendar settings

Use the Stock Calendar Maintenance window to change the stock count calendar, if needed. Changes to the stock count calendar won't affect the suggested stock count dates for items until the suggested dates are recalculated.

To change stock count calendar settings:

- Open the Stock Calendar Maintenance window.

(Inventory >> Setup >> Stock Calendar)

Make changes as needed. If you change the status of any day—changing an up day into a down day, for example—an alert message appears, warning that the changes won't be reflected in any current dates for stock counts. Choose Yes to continue.

Choose OK to save your changes and close the window.

Chapter 9: Reason codes

A reason code is used to identify causes for item stock movements and adjustments. Once reason codes are set up they can be assigned to a line item on inventory adjustments, variances, transfers and stock counts.

This information is divided into the following sections:

Creating reason codes

Modifying reason codes

Inactivating reason codes

Deleting reason codes

Creating reason codes

Before you can begin using reason codes on inventory transactions, define the settings you want to use.

To create a reason code

- Open the Reason Code Setup window.

(Inventory >> Setup >> Reason Code Setup)

Enter an identifier, such as Spoilage, and a description for the reason code.

Select which inventory transactions this reason code will be entered on. The transaction type will limit the reason codes available in a lookup window to only those that apply to the specific transaction you're entering.

Select the types of adjustment and variance transactions to more specifically broaden or limit the use of this reason code.

If you select Adjustment or Variance, select a default offset account which will be used to track amounts posted with this reason code. For example, if you use Spoilage as a reason code, and enter it every time you enter a decrease adjustment for spoiled items, you will be able to identify the costs of all spoiled items distributed to this account at the end of the year. If you do not specify an offset account, the item amount will be posted using the standard account distributions for the item.

Select the types of transfer transactions you'll use the reason code on. The reason code can be assigned to any combination of inventory and transfer transactions.

Choose Save.

Modifying reason codes

You may find as you're using reason codes that you need to expand the use, or more further limit the future use of a reason code. Changes you make do not affect existing transactions containing the reason code.

To modify a reason code

- Open the Reason Code Setup window.

(Inventory >> Setup >> Reason Code Setup)

Select the reason code you want to change.

Make changes as needed. Existing transactions are not affected by your changes.

Choose Save.

Inactivating reason codes

A reason code can be inactivated at any time. Once it is inactivated, you won't be able to enter it on any new transactions. Existing transactions are not affected by inactivating a reason code.

To inactivate a reason code

- Open the Reason Code Setup window.

(Inventory >> Setup >> Reason Code Setup)

Select the reason code you want to inactivate.

Mark Inactive.

Choose Save.

Deleting reason codes

A reason code can be deleted at any time. Existing transactions are not affected by deleting a reason code. The code will remain on the transaction as a means of maintaining history.

To delete a reason code

- Open the Reason Code Setup window.

(Inventory >> Setup >> Reason Code Setup)

Select the reason code you want to delete.

Choose Delete.

Part 2: Cards

This part of the documentation includes information that will help you create and modify cards for Inventory Control. You can refer to these procedures whenever you need to create or modify a record for a new item or site. Information about viewing and deleting records also is included in this document.

You'll need to complete these setup procedures before you enter transactions.

The following information is discussed:

Chapter 10, "Item cards," describes how to create and modify item records.

Chapter 11, "Standard price lists," describes how to specify costing and pricing information for items for standard pricing.

Chapter 12, "Extended pricing," discusses how to set up extended pricing information.

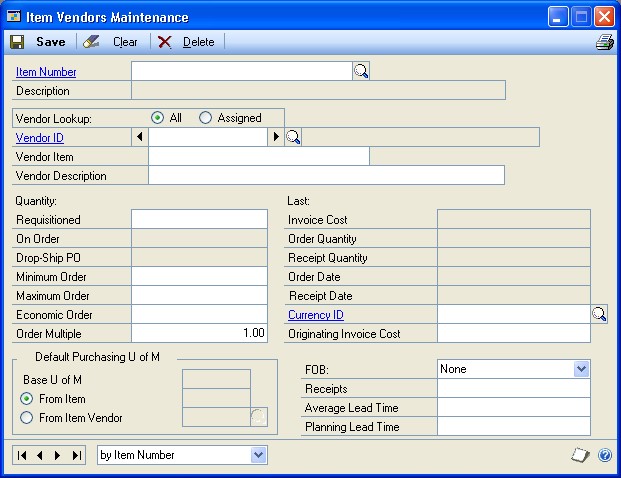

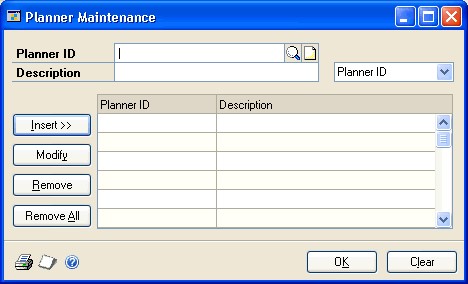

Chapter 13, "Purchasing options, vendors, and planners," contains information about purchasing options, including specifying vendors.

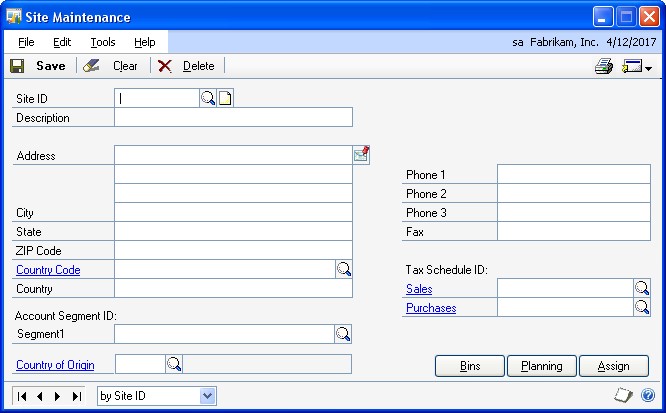

Chapter 14, "Sites and beginning quantities," includes information about setting up sites and creating item-site relationships.

Chapter 15, "Item-site details," explains how to enter information about sites for items.

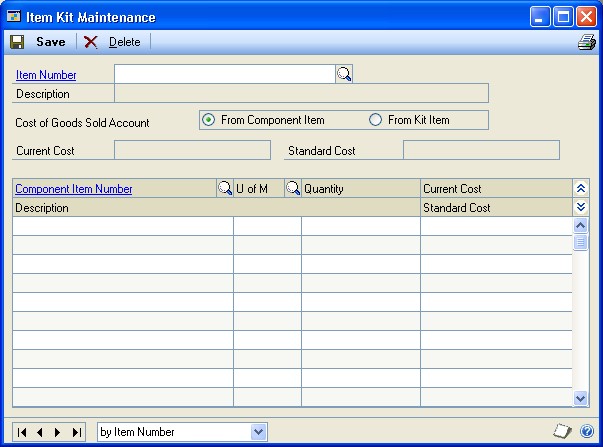

Chapter 16, "Kits," explains how you can use kits to work with collections of items that are sold as a unit.

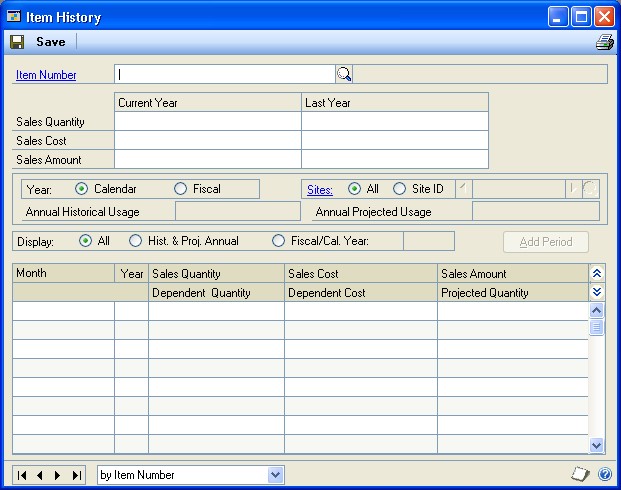

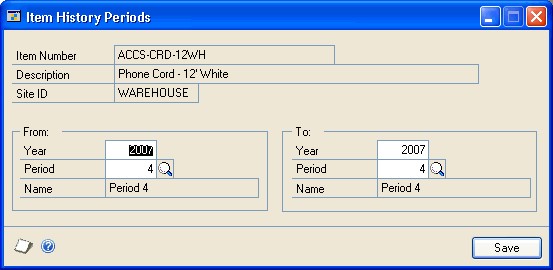

Chapter 17, "History," contains information about keeping history for your item records.

Chapter 18, "Count intervals," includes information about specifying how frequently an item should be counted at a specific site.

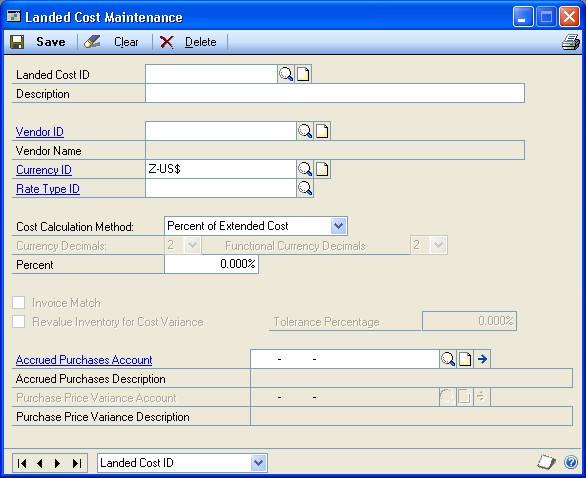

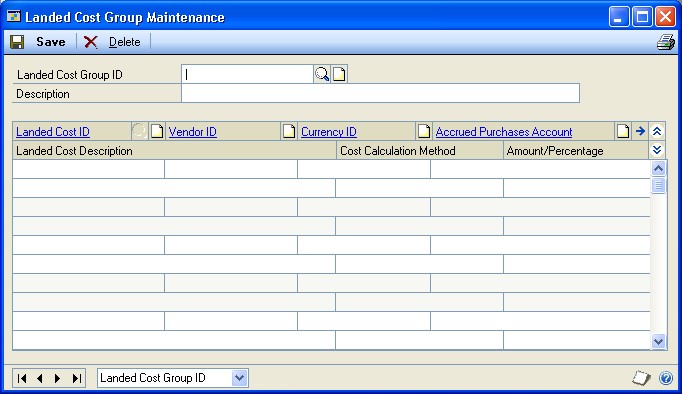

Chapter 19, "Landed cost cards," describes how to create and group landed cost records, and how to assign the groups to item-site (or item-site-bin) combinations.

Chapter 10: Item cards

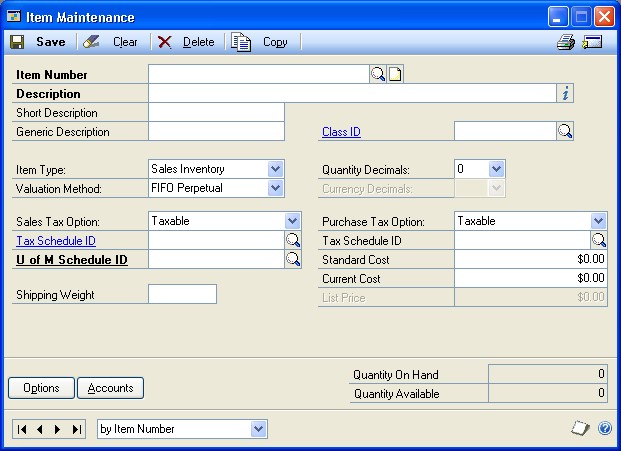

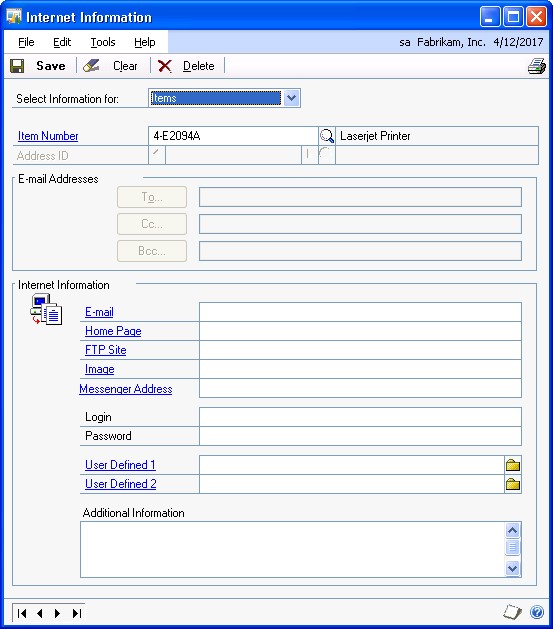

When you enter an item record in Inventory Control, you can enter much more information than just an item number and description. You can use Inventory Control to add Internet information, to choose what types of history to keep, to specify posting accounts, and to designate substitute items.

If you're using Multicurrency Management, you also can assign currencies to items. To be able to purchase or sell items in currencies other than your own, you must first assign the currencies to the items.

The following information is discussed:

Setting up a numbering system for items

Creating an item record

Entering Internet information for an item

Entering item options

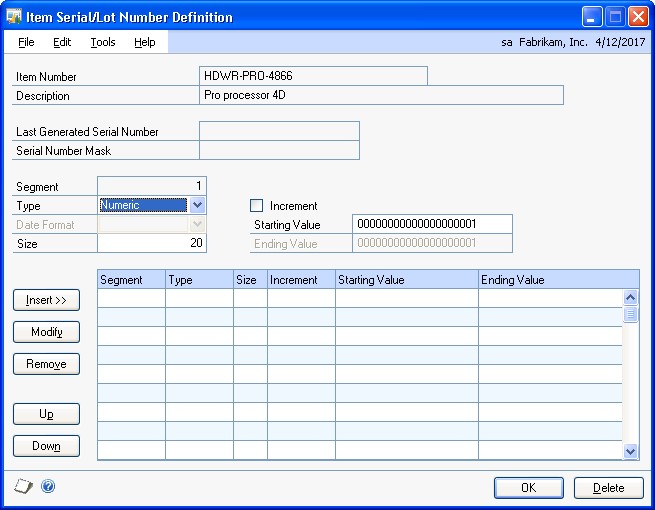

Defining a serial number mask

Defining a lot number mask

Assigning posting accounts to items

Assigning suggested sales items to an item

Assigning a currency to an item

Item numbers and substitute items for customers

| Sorting without leading zero | Sorting with leading zero |

|---|---|

| WIRE-10 | WIRE-008 |

| WIRE-8 | WIRE-009 |

| WIRE-9 | WIRE-010 |

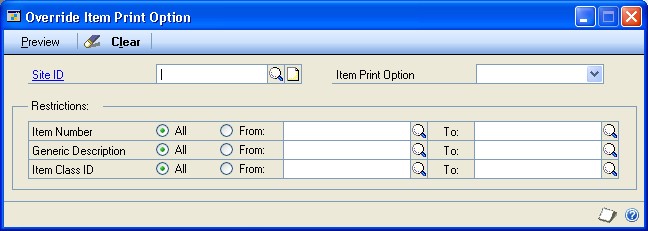

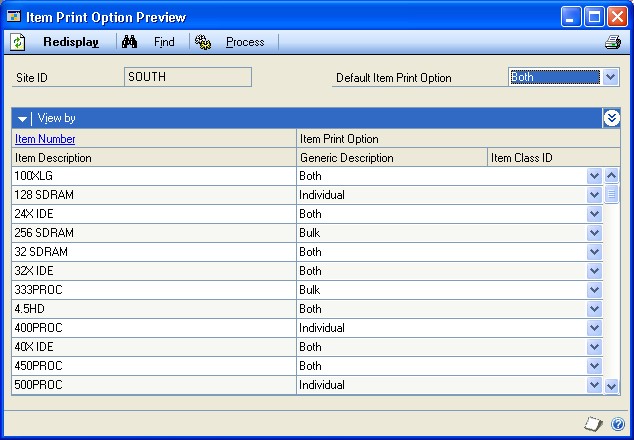

Changing the item print option for an item

Copying an inventory item

Understanding item record modifications

Modifying an item record

Removing a currency from an item

Inactivating an item

Deleting an item

Setting up a numbering system for items

As you begin setting up your items, consider how you want to number existing and new items. For example, you can assign specific groups of numbers to different types of items. Once you've determined the most appropriate numbering system for your company's inventoried items, use it consistently for the best results when printing reports or completing maintenance procedures.