Set up warehouse management

When a company is in the process of implementing warehouse management, basic setup must be completed to make sure that the system works for the company's business needs.

Storage dimension groups

Storage dimension groups are an inventory dimension that are used to determine inventory storage information for your items, and how you will store or retrieve your inventoried items. You can set up multiple storage dimension groups to fit the needs of your business. For example, you may have some products that are stored by site and warehouse, and you may have other items that are stored by site, warehouse, and location.

Storage dimension groups can be configured in Product information management > setup > Dimension and variant groups, the Use warehouse management process option indicates that the warehouse management functionality will be used for all products that are assigned to this storage dimension.

The Inventory status option is used to divide inventory into categories, such as Available or Not available. It also can block certain activities in case certain items are not available in inventory.

For example, if you want to prevent a worker from picking the items for any orders, use the inventory blocking feature, which prevents the use of items that are not available.

The License plate inventory dimension can be used to track inventory that is grouped together in a warehouse, such as the pallet, bin, cart, or individual item.

If you want to use the warehouse management processes and apply a reservation hierarchy, you must set up at least one storage dimension group with at least one storage dimension.

Tracking dimension groups

Tracking dimension groups are used in Supply Chain Management to enable you to keep track of your items in your facilities. For example, you can track your items by serial numbers, batch numbers, or ownership.

- Serial numbers can be used if you have items that are unique, or you would like to track your items on a single-item basis. Batch numbers can be used for groups of items.

- Batch numbering is also beneficial for tracking issues with production or shipping.

- Ownership can be used if you are storing items that are owned by a third party and not your organization.

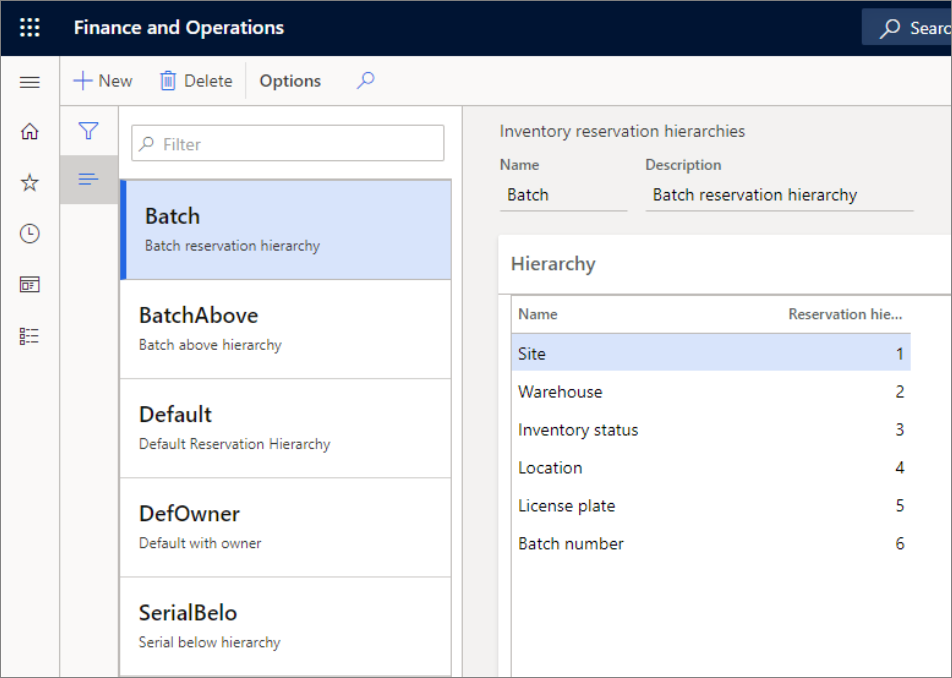

In warehouse management, tracking dimensions are optional for Reservation hierarchies, found in Warehouse management > Setup > inventory. Tracking dimensions are typically used as batch control or to serialize inventory. When you select to enable a serial number dimension, you have an option to define when the serial number will be captured in the warehouse management process.

Override the default reservation principle for materials in production

When you create a new production order or batch order, you'll be asked to choose the reservation principle that will apply to the order and all of its BOM lines or formula lines. Any or all of the BOM or formula lines can override the reservation principle established for the relevant item model group and use the reservation principle specified for that item model group instead.

By default, you can define a default reservation principle for each item model group. Production bill of materials (BOM) or batch order formulas often require different reservation principles. Select which default reservation principle will be used for an order, as well as what reservation principle will be used instead (manual, estimation, scheduling, release, or start).

For example, if you have raw materials or ingredients that require picking, any BOMs or formula lines developed for those goods must include a physical reservation, because physical reservation is required for the generation of warehouse work. If you want the reservation to automatically happen, you typically choose one of the reservation principles: estimates, scheduling, release, or start. If you have materials or ingredients that don't require pick labor because they're taken directly from a location, you'll probably choose the manual reservation concept, which doesn't make any physical reservations or generate any pick work.

For more information, see Override the default reservation principle for materials in production

Unit sequence groups

A unit sequence group must be assigned to any item that has a storage dimension group that uses warehouse management.

The unit sequence group defines the sequence of units that can be used in warehouse operations. The sequence determines the order of units in which warehouse work is generated, and it is applied when work is created for quantities on a purchase order line or transfer order line. The unit sequence group should include units of measure that range from the smallest to the largest unit and can be used for the product in warehouse operations.

The important features of the Unit sequence groups page are:

- Each unit of measure can be selected if you will allow that unit to be used in cycle counts.

- You can select a unit of measure as the default unit of purchase orders, production, or material consumption.

- You can specify a default container type for the unit.

If you want to receive an item larger than a pallet size and have it grouped, select The License plate grouping field. If this option is not selected, every single item above the pallet unit would be assigned its own license plate.

Inventory statuses

The inventory status dimension can be used to divide items into categories, such as Available and Blocking. You can create an unlimited number of statuses. Additionally, you can set the default for the inventory status to apply for all items, for items in one warehouse, or to one customer or vendor.

After you have set up an inventory status, you can set the default inventory status for a site, item, and warehouse. You can change the default status on a mobile device or on the purchase order, sales order, or transfer order line.

Item groups

Items groups are also used to group items together that all share a similar posting profile. This way, you don’t have to set up a posting profile for every item you have in the application. The information within the item group is used for several transactions in the system. For example, when a transaction occurs, the item group assigned to the items within the transaction will be used to determine which ledger accounts the transaction will be posted to.

In the item groups, you might need to set up the use of filters. Filters, which are used to further describe an item, can also be used to limit items for vendors and customers and can be made a required setup for a product.

Filters allow users to categorize items, limit customers to items, and then limit vendors to items. For example, you should use the filters if there is a requirement to only sell items that have that specific filter.

Four filter codes are available in Supply Chain Management. Make sure you predefine the values for each filter code and consider renaming the filter codes from the generic labels of code one, code two, and code three to match your business use of the filter code.

Filters are turned on and off on the Item groups page.

The Use filter code option indicates that you'll be using the filter code for the item and that you'll manually set that filter code on the Released product page. You can also set up filter groups, which will automatically default to filter codes based upon the item group selection when you create a new product.

After you create the filter codes, you can then configure items to be generally available, which overrides any customer or vendor-specific filter codes, or you can add the filters to your customers and vendors.

Dock management profiles

The dock management profile helps you control inventory items for multiple orders, shipments, loads, or waves at the docks when inbound items are received or outbound items are loaded. The location profiles also specify whether a warehouse location is license plate controlled, can be cycle counted, and whether it allows for mixing of inventory batches.

You can set up a dock management profile and assign it to a location profile to manage the mixing of inventory in specific warehouse locations.

For example, when you stage product into a staging location, perhaps you only want one order to be staged in each staging lane, or to segregate items by shipment ID, load ID, order number, wave ID, and work order type.