Planning Optimization support for capability-based resource allocation

Important

This content is archived and is not being updated. For the latest documentation, go to What's new or changed in Dynamics 365 Supply Chain Management. For the latest release plans, go to Dynamics 365 and Microsoft Power Platform release plans.

| Enabled for | Public preview | General availability |

|---|---|---|

| Users by admins, makers, or analysts |  Sep 30, 2021

Sep 30, 2021 |

Jan 14, 2022

Jan 14, 2022 |

Business value

Companies using Planning Optimization can optimize resource usage by deferring resource allocation until productions are scheduled. This flexible solution automates resource selection during production scheduling based on individual operation capabilities and requirements.

Feature details

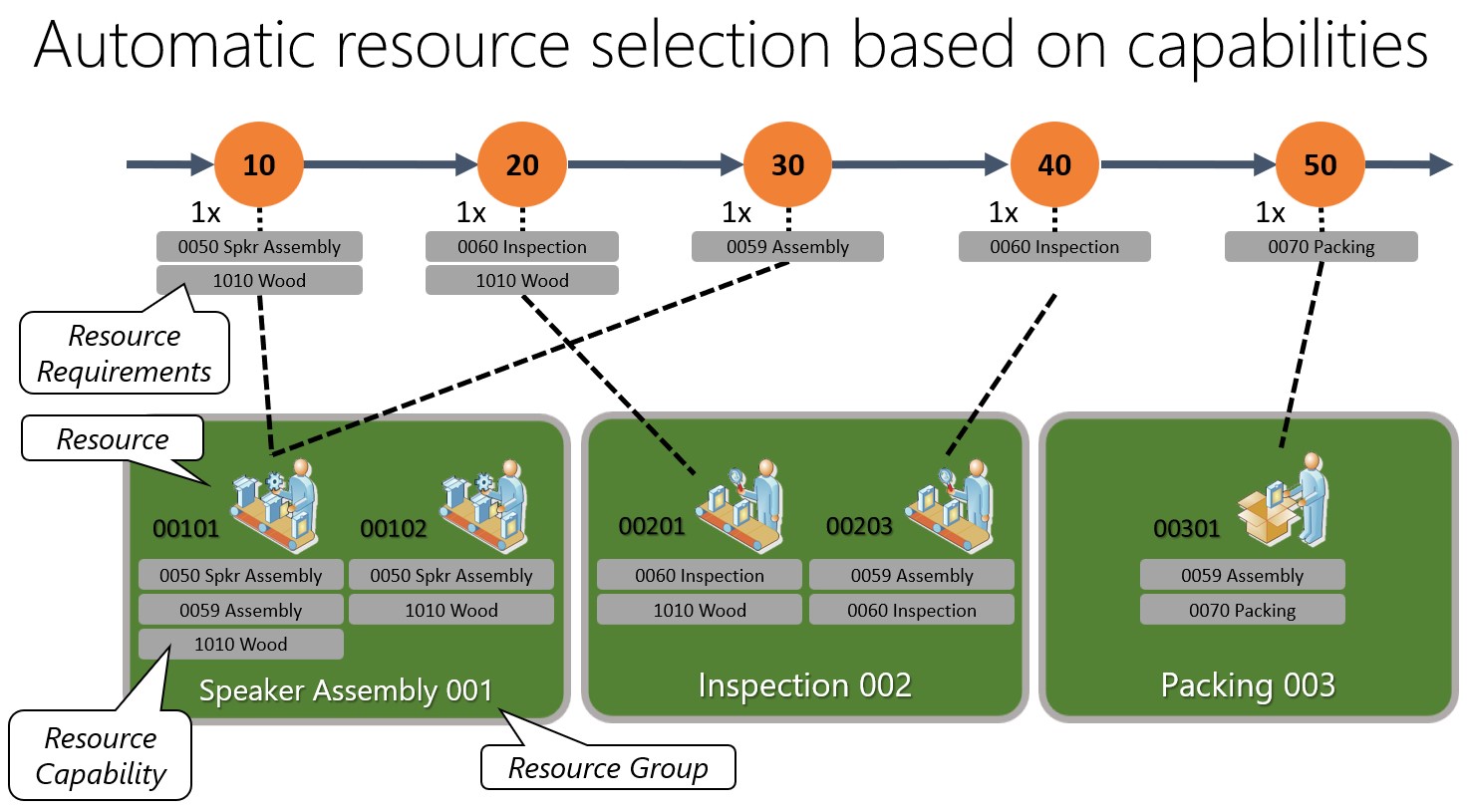

Planning Optimization now supports production scheduling with flexible resource allocation based on resource capabilities. A capability is the ability of an operations resource to perform a particular activity. An operations resource can have more than one capability assigned to it, and a capability can be assigned to more than one resource. Capabilities can be assigned to all types of resources, including tools, vendors, machines, locations, facilities, and human resources. Each capability can be set to ensure the selected resource has the required capability level for a given operation. Capabilities can also include a priority, which is used during scheduling to optimize the resource selection based on highest available priority.

Instead of assigning specific resources or resource groups to a route operation, you can define the capabilities required for each route operation. With this setup, scheduling will match the required capabilities with the capabilities of available resources to determine the resource assignment for each production job.

Capability-based resource allocation is part of the materials resource planning II (MRP II) support provided by Planning Optimization. MRP II helps planners at manufacturing companies control their production schedule, control resource load, and determine delivery lead times. Because Planning Optimization runs as a separate service, it's able to facilitate high performance production planning without slowing down the rest of the system.

With Planning Optimization support for production scheduling, manufacturers can benefit from:

- Significantly improved performance and scalability with in-memory processing.

- Minimized system impact on other processes made possible by moving master planning to its own service.

- Near-real-time insights into requirement changes during office hours.

For more information about the Planning Optimization migration process, including answers to frequently asked questions, see Migration to Planning Optimization for master planning.

Geographic areas

This feature will be released into the following Microsoft Azure geographic areas:

- United States

- Europe

- United Kingdom

- Australia

- Canada

See also

Scheduling with resource selection based on capability (docs)

Planning optimization support for capability-based resource allocation (learn)