Bills of materials

The bill of materials (BOM) is one of the cornerstones in the definition of the production process. Manufacturing companies use BOMs to track and plan which components are required to produce a product.

A BOM is a comprehensive list of all the components, parts, raw materials, assemblies and their quantities that are required to make a finished product.

BOMs are used to specify ingredients or subordinate components that are physically required to make each assembled part number or item in production. If a company only produces several simple products, production can be scheduled manually with the correct BOM parts arriving on the production floor, at the correct time, and at the proper resource.

Companies need to schedule and track their components and subcomponents in the most efficient, cost-effective way.

BOMs define the relationship between the components and the finished product or sub assembly. A clear definition of this relationship is important for the following tasks:

- Creating production orders

- Performing costing calculations

- Performing item planning, which ensures that the correct products are purchased and produced in the right quantities at the right time

- Ensuring correct stock levels

- Ensuring that correct components are used to build a quality product

Every item that must be financially accounted for in an inventory or in the costing phase must be included in the BOM. The level of detail to include is determined by the company's production and accounting needs.

For example, items such as nuts, bolts, screws, and nails are frequently not included in BOMs because the cost of tracking these items is higher than their actual value.

Although BOMs define the components and their relationships, they do not define the sequence of steps to produce or assemble the finished item. These steps are defined on the route.

Product concept

A BOM consists of products that are in your inventory. Therefore, it's important to remind you about product definitions, which are created independently of a legal entity. Core values such as product number, type, and name are shared values across all legal entities in the organization. Some core values can be overridden by a legal entity, such as the search name, whereas other values are kept as key definition attributes and therefore cannot be changed other than on the product definition.

- Product - A product is a uniquely identifiable product. It serves as a core product that does not vary; therefore, no product dimensions can be associated with the definition.

- Product master - A standard or functional product representation that is the basis for configuring product variants. The variations are configured by selecting a configuration technology, which can be determined either by a set of predefined product dimensions or by using product configurations in sales scenarios. Product masters serve as templates or models for variants. The variants of a product master can be either predefined or created in sales scenarios by using a product configurator. A product master is associated with one or more product dimensions.

- Product variant - A product variant is the configuration of a product master. Based on the choice of the configuration technology, the variant can be either predefined by using the product dimensions of its master or configured by using a product configuration tool.

BOMs can contain items or service types, which could have either product or product master subtypes with specific variants in Supply Chain Management, depending on whether the item is purchased or produced in-house.

The product types that are used in a BOM are as follows:

Item - These types are products that are purchased or produced but are frequently included in the production of manufactured (BOM) items. An item in a BOM that is defined as product type Item is either purchased from an outside source or produced in-house, depending on the Default order type setting. When the Default order type is set to Purchase order, then the item is purchased. When the Default order type is either Production or Kanban, then the item is manufactured.

Service - These types are items that are used, such as the service that you are buying when you are sourcing an operation in a production order to a vendor, which is called subcontracting.

An item in a BOM that is defined as product type Service represents and quantifies a service that is part of the manufacturing process. For example, an item of type Service can be the number of hours that are entered by each resource for services that are performed during the manufacturing process.

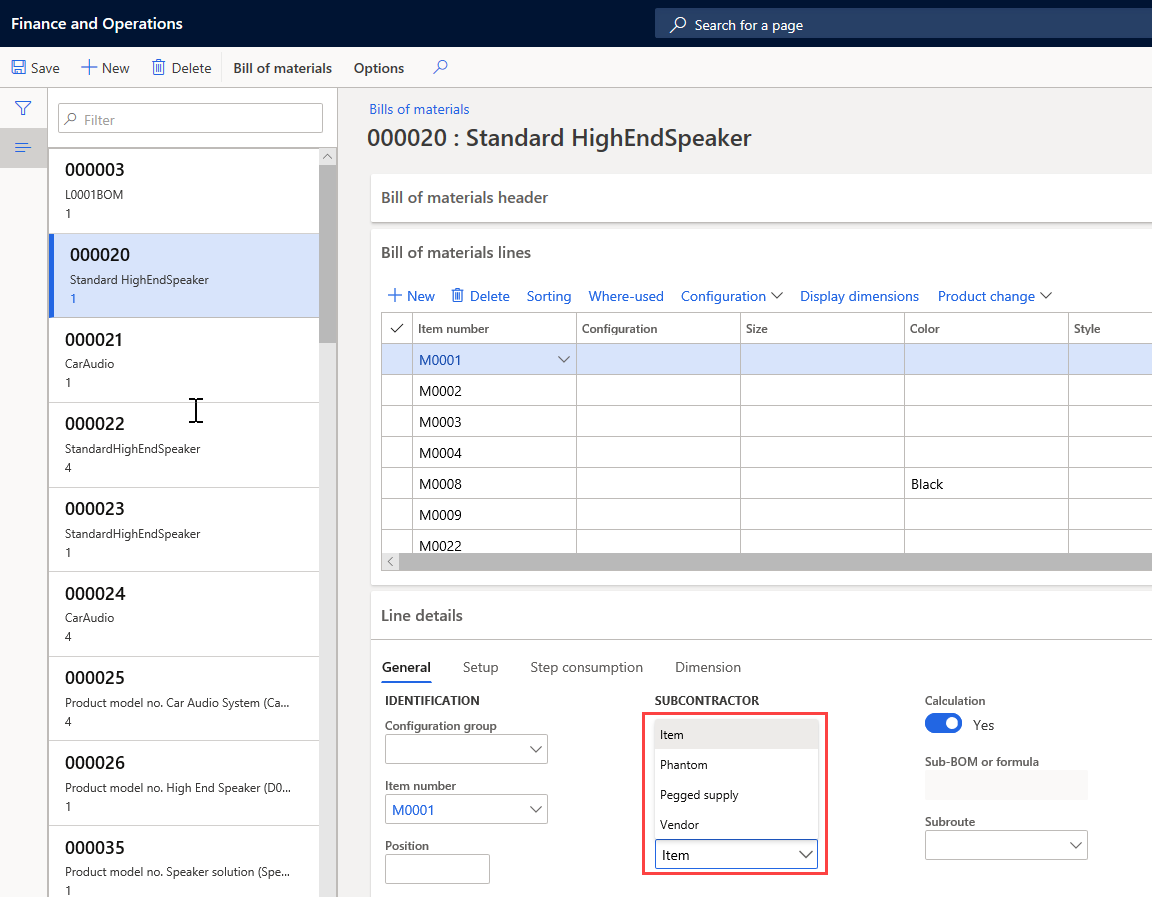

BOM line types

The BOM line types are as follows:

Item - Select this line type for materials or services that are directly consumed and that don't require further explosion or pegged supply.

Pegged supply - When you are using this line type, a reference production order is created for the BOM line item when the production order is estimated.

When a BOM line is set to Pegged supply, then that item will be pegged (signaling a product demand requirement) according to the method of production (lean or normal) and not fixed by a warehouse.

Phantom - This line type is basically a placeholder for components that are not tracked if they are in production but are instead included and accounted for in the master BOM. Phantom BOMs enable Master planning to calculate requirements for the needed components, even though the item is only occasionally used in the manufacturing process. See the Phantom items for an example.

Vendor - These types are components that are purchased from an external vendor. In this case, a purchase order is automatically generated when a planned order is firmed.

When the production is created manually, the purchase order is created when the production order is estimated.

Product Information Management > Bills of materials and formulas > Bills of materials

Scenario

A legal entity that makes flashlights uses a BOM that contains a plastic body, lightbulb, battery, and lens. John, the Materials manager, purchases lightbulbs, batteries, and lenses.

You do not have to purchase the plastic bodies because they are produced in-house.

When creating the BOM for the flashlight, John first enters the lines for the lightbulb, battery, and lens by using the Item line type. John then enters the plastic body of the flashlight in the BOM that is produced in-house by using the Pegged supply line type. This process helps guarantee that a production order for the body is created when the production order for the finished good is estimated.

BOM features

The following list describes BOM features:

Version control - Allows for the phasing out of an older or no-longer-used component. BOMs can be set up with multiple versions that have different effective dates.

Sub-BOM control - Allows for sub-BOMs to be sold or planned, either independently or at the same time as the parent production.

Subcontractor support - Use this feature to automatically generate purchase orders to external vendors when master planning is run.

Quantity-dependent BOMs - Quantities on BOMs can be used to control which version of the BOM is used in production. For example, if fewer than 500 pieces of a BOM are ordered, version 1 is used, and when more than 500 pieces are ordered, version 2 is used.

Multisite BOMs (and routes) - A finished product can be set up so that part of it can be made at a different production site. This setup is performed by using the different levels in the BOM structure to assign where the components are to be produced. When multiple sites share inventory with the same item number, the BOM (and route) can be set up so that the components of these products can be produced at different sites. When this feature is used, the corresponding routes must also be defined based on site.

Phantom BOMs - Phantom BOMs allow the deduction from inventory to occur only when the component is needed in the production. Select the Phantom line type when you want to explode any lower-level BOM items that are contained on the BOM line.

In Master planning, in planned cost calculation, or on estimation of a production order that uses BOM lines of the Phantom type, the parent BOM line that refers to a product variant that has a phantom BOM is replaced by the component items that are listed as BOM lines in that BOM, as determined by the applicable active BOM version of that product variant. If the product variant has an applicable active route, the operations of that route are merged into the parent route.

Phantoms are typically used to simplify the engineering process. Extensive use of phantom BOMs in many levels will influence performance, especially in highly repetitive manufacturing scenarios. To improve performance, you should avoid deep hierarchies of phantoms. Instead, use pre-exploded production BOMs and routes.

BOM versions

Each BOM can have a variety of BOM versions if different dates, sites, product dimensions, or quantity intervals are defined for each version. It is a specific configuration of a bill of material to include an item. An unlimited number of versions can be allocated to BOM items. Versions enable items to be associated with many different BOMs.

You can create a BOM without a BOM version; however, to link a BOM to a product, you need a BOM version. You can have unlimited number of BOM versions, but only the active BOM version is used for the production orders.

The BOM version links the BOM and the product to produce the finished goods. A product can have zero or many BOM versions. A BOM version can be approved and then can be activated. The active BOM version is used for finding the default BOM when you are creating a production order for the product.

BOM versions are the link or reference between a product and the main BOM. BOM versions allow the same products or components to be associated with many different BOMs.

BOM versions can be Active or Inactive. Active versions are the only versions that are recognized by the system outside of the BOM functionality. The Production control module, for example, uses only active versions. You can specify that no versions are active, or that a variety of BOM versions are active for any product at any given point in time. However, only one version at a time is applied. The applied version is selected based on time, site, or quantity. However, different versions can exist based on product dimensions, such as color, size, and configuration.

For planning, calculation, and consumption purposes, each BOM line must specify whether the item has any configurations. A configuration is a standard component combination, such as a satellite speaker and a subwoofer that can be specified for a BOM item during the ordering process.

The BOM version enables ongoing changes to be made to the item and different configurations to be employed depending on the manufacturing circumstance. Version control also supports phasing out of old components so that new components can be produced or bought.

Version control methods allow you to start and stop the production of selected BOM versions. All BOM versions have an expiration date. However, this date can be preempted if you validate a new version. The validation of a BOM version automatically tells the system to phase out the old version and to make the new one active. The system then immediately starts to plan and buy based on the information in the new active BOM version.

For example, a company decides to start production of its best seller, a subwoofer model, at its second operational site. Therefore, a new BOM version of this subwoofer model, identical to the main version but for a different site, is created, approved, and activated.

Besides making a version active or inactive, Supply Chain Management offers several other ways to control which BOM version is used in production. These methods include Date and quantity and Site control.

Legal entities can create multiple BOM versions (identical in quantity and dates) that are produced at different sites. In this case, you can create a BOM version on the BOM line page and specify the site for which the BOM version is valid in the Site field. (If site is not specified, the BOM version is valid for all sites.)

Version control based on site allows you to control which BOM versions are ready for production, depending on the site where they are produced.

Legal entities can assign a BOM to multiple products or versions, depending on where it originates and if the product must go through different manufacturing processes. For example, the product might be processed by different resources or have different routes.

It is common industry practice for legal entities to use the same ID to create a product at different sites by using different routes. To support this situation, you can define a general BOM version that does not specify a specific site or warehouse. In this situation, the BOM line consumption is assigned to the resource and becomes a part of resource consumption. The resource references a production unit, which also states the picking warehouse.

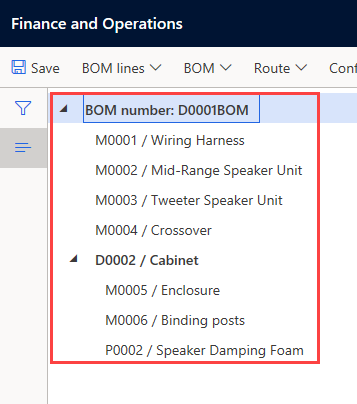

BOM levels

A single-level BOM consists of the immediately subordinate components that are necessary to build the product and does not contain sub-assemblies.

When a BOM contains another BOM as its component, then it is known as a multilevel BOM, where the sub-BOM is referred to as level one and its components as level two. BOMs can consist of as many levels as necessary, depending on the type of product being produced. A multilevel BOM is often illustrated graphically in a tree or outline structure.

Product information management > Bills of materials and formulas > Bills of materials > (Select item) > Maintain > Designer

Watch this video for an introduction to the BOM designer.

In Supply Chain Management, BOMs can consist of as many levels as necessary, depending on the type of product being produced. That is, any given component in a BOM can also be set up to contain a BOM of its own.

Complex BOM items frequently have several sub-BOMs. The number of levels, or sub-BOMs, that a BOM has depends on how the item is managed. Generally, an item needs its own level in the BOM if, at a stage, the item must be:

- Tracked

- Stored

- Sold

Example

Adult bicycles consist of two wheels, a seat, handlebars, and a frame. All these components are reflected in the bicycle BOM. However, the frame also consists of several discrete items (three or four tubes welded together). Therefore, the frame has a BOM of its own called a sub-BOM, that is, a BOM within the BOM for the end-product, the bicycle.

Assume that a BOM is created to assemble bicycles. The following items are set up as the product type. The product types are used in the BOM and do not require assembly.

- Wheels

- Seat

- Handlebars

The bicycle frame is assembled in production. This part of the process is set up as a BOM. However, a sub-BOM includes the following items:

- Tubes

- Welding wire

- Brackets or brace

Site-specific BOMs and routes

Site-specific BOMs and routes are created to allow for the automatic selection of the correct BOM, route version, and product dimensions when you are working with multiple sites. The main elements of the site-specific feature are:

- BOM and route selection, based on the site and product dimensions, is considered in Master planning.

- For BOM versions that are not site-specific, the user can select the Resource consumption check box on a BOM line as an alternative to the issuing warehouse that is indicated on the BOM line.

It is common practice for the same BOM to be used to produce an item at different sites by using different routes. To support this practice, you can define a general BOM version that does not specify a site or a warehouse. The resource, through its assigned resource group, references a production unit, which further states the picking warehouse.

Production at multiple sites might involve a BOM whose component items can be produced at and moved between different sites, and the sites share common item numbers. BOM versions for the component items must be structured to support the mandatory site dimension.

A finished product can be set up so that part of it can be made at a different production site. When multiple sites share inventory that has the same item number, the BOM and the route can be set up so that the components of these items can be produced at a different site. When this feature is used, the corresponding routes must also be defined based on site.

When planning materials and resources in an environment that has multiple production sites, the system selects the BOM version and the route version based on the site of the requirement, a valid date interval, product dimensions that are active for the item and the quantity.

BOMs in the product lifecycle

In the product lifecycle, many types of BOMs might be created for various reasons:

- Sketching/Draft BOM - This BOM gives a draft estimation of required materials in an early design phase and helps you prepare a rough estimate of cost and estimated product attributes.

- Engineering BOM - This BOM is typically used when you design products that are based on existing product portfolios. Engineering BOMs are structured to simplify the design process and group complex products into engineering modules. For simple products, it might be possible to use engineering BOMs for the actual production process. However, for other products, the engineering BOM must be converted to an actual production BOM. Engineering BOMS are typically represented by phantoms in the BOM hierarchy. Though engineering BOMs can be used for the planning and implementation of manufacturing operations, this approach can lead to inefficiencies, especially in repetitive operations where many orders are created.

- Planning BOM - This BOM is used to plan for material requirements. The demand of components and ingredients is calculated based on the demand of the finished products. Like costing BOMs, planning BOMs might represent a specific mix of material that is used in a period.

- Production BOM - The BOM that is used for a specific production. A production BOM must consider the actual resources that are being used to produce the product. When a production order, batch order, or kanban is created, the multiple levels of BOMs that are represented by phantoms are collapsed into one level and distributed over the operations for the order.

- Costing BOM - This BOM is used to calculate the estimated cost of a product. For example, you can use a costing BOM when standard cost is used or when the estimated planned cost of a given product is calculated. Costing BOMs can refer to the expected use of a specific mix of materials and resources. Therefore, you can use the costing BOM to create a representative estimated cost for a period and help avoid variances over time.

The types of BOM that are used in an implementation depend on the implementation and on the business scenarios and requirements. In simple implementations, a planning BOM, production BOM, and costing BOM can be modeled as one BOM. In environments that have frequent engineering changes and multiple alternative routes, a larger set of BOM types will probably be required.

The overall process of creating BOMs is as follows:

- Create the finished product, which will be linked to the BOM through the BOM version.

- Create all products that will be components of the BOM.

- Create the BOM.

- Create BOM version(s) that associates the finished product and the BOM, and then approve and activate it. This task is performed either before or after the component products are added.

- Add products to specify which items to include in the BOM. These products are BOM lines.

- If necessary, you can create configurations and associated rules for the BOM.

- Create site-specific BOM/routes to allow for the automatic selection of the correct BOM and route version and the item dimensions, if you are working with multiple sites.