Overview

The following figure illustrates the flow and activities that are needed to create a configuration model.

Go to Product information management > Setup > Product information management parameters to set up constraint-based product configuration model parameters before you create a product configuration model.

The following parameters are available:

Number sequence for the Constraint-Based product configuration model - Uniquely identifies all the configurations that you create. A number sequence must be defined to uniquely identify the product variants that you create.

For example, when Susan, the Order Processor, configures an item on a sales order, a number is pulled from this number sequence. The number is stored in the Configuration dimension field for the product on the order line.

Item lookup method - Determines whether configurable items display together with all the other items or if you want them to display on a separate tab.

The following values are used:

Default - Displays product configuration models on a list together with other items that are available when you select an item on a sales order line.

Configurable - Displays product configuration models on a separate tab when you select an item on a sales order line.

Configuration documentation type - Lets you add a note to the order line. The note will show the results of the configuration that you created.

Default configuration ID - Sets the initial name of the configuration for product variants that, as a standard, are released together with constraint-based product masters.

Use cache for configuration - Is used to reduce the amount of time it takes to launch the Product configuration models page.

Attach - Enables you to attach a sales price breakdown that is created for a product configuration model from a sales order line. Select this option to choose a format, such as a file or an image, for the sales price breakdown.

Default currency - Use this parameter for a price configuration model. Specify a default currency if you want to set up a price model for a product configuration model.

After setting up the parameters, you can choose from several processes that are typically used for building a product configuration model.

Components

Components are the main building blocks of a product configuration model, and most information about the model is related to them. Components are defined once and can be used many times in one or more product configuration models.

Product information management > Products > Product configuration models > New

After you assign a component to a product configuration model, you can add information to the component so that it suits that particular product configuration model. This added detail can include information about user requirements, attributes, constraints, BOM lines, and route operations. A component can also include other components as subcomponents.

You can use a component multiple times in a product configuration model, and the component can be reused in multiple product configuration models.

For example, when you are creating a product configuration model for a home theater system, you can create components such as a video system and audio system. The audio system can also consist of two components such as a receiver and speakers. The receiver and speakers are known as subcomponents of the audio system.

Only items that have Constraint-based configuration as the Configuration technology on the Released product details page can be used as components to build a product configuration model. Otherwise, the item cannot be selected on the Subcomponents FastTab on the Constraint-based product configuration model details page.

Attribute types - Specify the set of data types or domains for attributes that are used in a product configuration model in Product information management > Setup > Categories and attributes > Attributes. The following data types can be used in a product configuration model: text, Boolean, integer, and decimal.

You can use decimal values, text without a fixed list, and integers without ranges in a product configuration model. However, you cannot use these data types when you write a constraint.

Microsoft Solver Foundation (MSF) constraint solver only supports text with a fixed list, Boolean values, and integers with ranges. Currency and DateTime data types are displayed in the list in the Type field. However, they cannot be used in a product configuration model.

Product configuration model - Is created to represent a generic product structure in Product information management > Products.

Attributes - Each component has one or more attributes that identify its properties. The attributes are what the users will have to select from during the configuration process.

Product model attributes are defined by using a domain that restricts the values that a user can select. Attribute values can be used in constraints to additionally reduce variability. You can also specify that an attribute value is used only when a certain condition is present. Like expression constraints, conditions are written as an Optimization Modeling Language (OML) expression.

Attributes describe the properties of the components. You can use attributes to specify the features that can be selected when a distinct product variant is configured. Each component has one or more attributes that identify its properties. The attributes are what you will select from during the configuration process.

A default value can be set for an attribute. The default value is used in the configuration user interface when the product configuration model is configured. Attributes can be mandatory. If an attribute is mandatory, you must set a value when the product is configured. You can also set a condition for a mandatory attribute. If the condition is met, you must enter a value for the mandatory attribute.

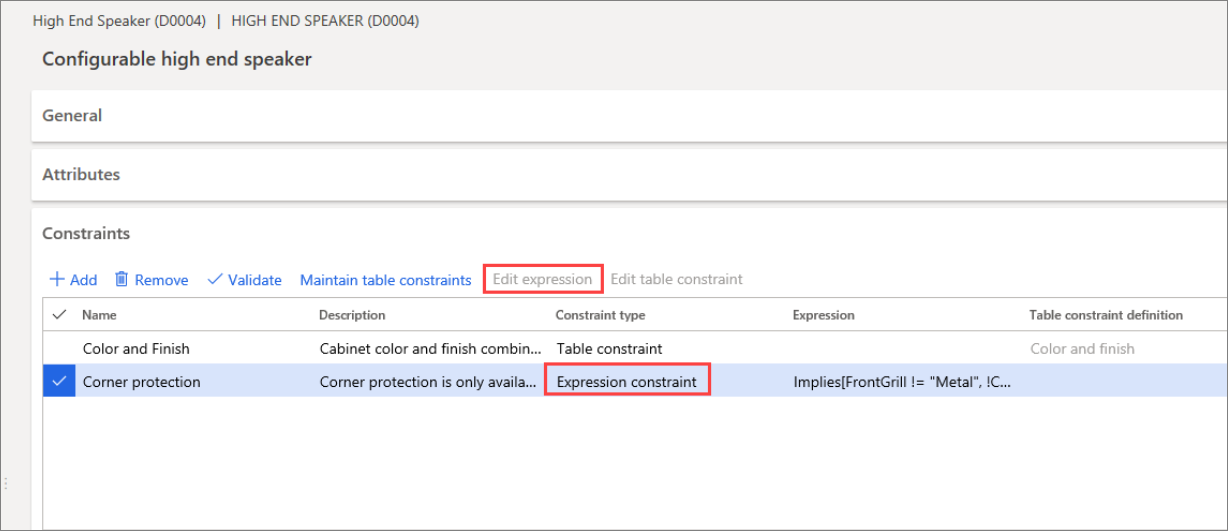

Constraints - Describe the restrictions of the product configuration model. Constraints are used to help guarantee that only valid values are selected when the product configuration model is configured.

Product configuration supports expression constraints and table constraints. Use expression constraints to express relations between attributes to confirm that compatible values are selected when you configure a product. Product information management > Products > Product configuration models

Table constraints - Are expressed in a table that explicitly defines the combinations to turn on for a specified set of attributes. The constraints are processed by the MSF constraint solver.

Calculations - Represent a mechanism for performing arithmetic operations in a configuration model. For example, a calculation can determine the length of a specific piece of raw material or the processing time for a polishing operation. Calculations are imperative and set the value for a target attribute after all the attribute values that are included in the calculation expression become available.

Subcomponents - Reflect the tree structure of the product configuration model. Because subcomponents reference existing components, they encourage the reuse of components in multiple product configuration models.

A subcomponent is used to create a parent/child relationship between two components.

User requirements - Represent a user-friendly abstraction between user requirements and specific components and attributes. A user requirement has all the properties of a subcomponent. However, you cannot map a user requirement to a product master.

BOM lines - Are included to identify the manufacturing BOM for each component. A BOM line must reference a product master or any released product, and all properties can be set to a fixed value or mapped to an attribute.

Route operations - Are included to identify the manufacturing route and must reference a defined operation.

Tailoring the configuration user interface - You can organize and arrange attributes and subcomponents into attribute groups or by moving them up and down in the user interface tree structure.

Validating a product configuration model - Validation of a product configuration model can occur on several levels in the model and could include validation for the following: constraints, BOM line conditions, route operation conditions, or the complete product configuration model.

Testing a product configuration model - After you set up a product configuration model, you can test that the model performs as expected by simulating the configuration process.

Building Configuration Templates - One or more configuration templates can be created to either speed up the configuration process or promote certain attribute combinations. The latter case could be a response to a sales campaign that places the focus on a certain set of product features.

Adding Configuration Translations - If the product is to be sold in different countries and/or regions, translations can be created for all text that appears in the configuration user interface.

Creating, Approving, and Activating Versions - The final and most important step in the process is to create a version for the product configuration model. The version represents the relationship between the product master and the product configuration model. You can select the version to configure an order or quotation line. A version must be approved and activated before it can be used in a configuration session.

Product Configuration Access - The purpose of the configuration process is to create a distinct variant of the product that meets the requirements of the customer.

Scenario

The Product designer, must create a new product model that includes several components for a home theater system and make the product model available in many countries and/or regions.

Attributes must be defined that characterize the capabilities for each component, and constraints must be created for the components to restrict the allowed product variants. BOM lines are added to represent the parts that are required to build the product together with the route operations.

Different types of services must be offered to the customer. These services allow for setup and installation of the home theater system and include repair services. The Product designer must be able to test the configuration and verify that the attributes and constraints are correctly defined.

To help speed up the configuration process when the Order processor, enters customer sales orders, the Product designer will create templates for the most popular versions of the home theater system.

The Order Processor, must be able to select from the templates that the Product designer created, or manually configure the sales order by using the options that they have provided to satisfy the customer requirements.