Generating put away work when reporting as finished from the Dynamics AX client

This new functionality is available with KB 2999768 and will be included in Microsoft Dynamics AX2012 R3 CU8. To find the HF you can use LCS Issue Search.

What's new?

In the AX2012 R3 release put away work could only be generated when you used the reporting as finished process on a mobile device for a production or batch order. In CU8 put away work can now also be generated when you use the reporting as finished process for a warehouse-enabled item from the AX client.

In this blog I am going to walk through two scenarios showing how put away work is now created when reporting as finished from the Dynamics AX client. In this example I am going to use item L0101 from the USMF demo data company

Simple scenario : Shannon has completed the assembly of ten speakers in her work cell. She reports the speakers as finished in the route card journal and put away work is generated.

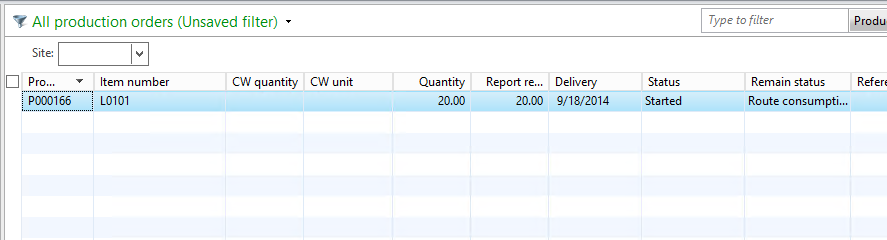

A production order for twenty pieces of mini-speakers exists and is in the status Started:

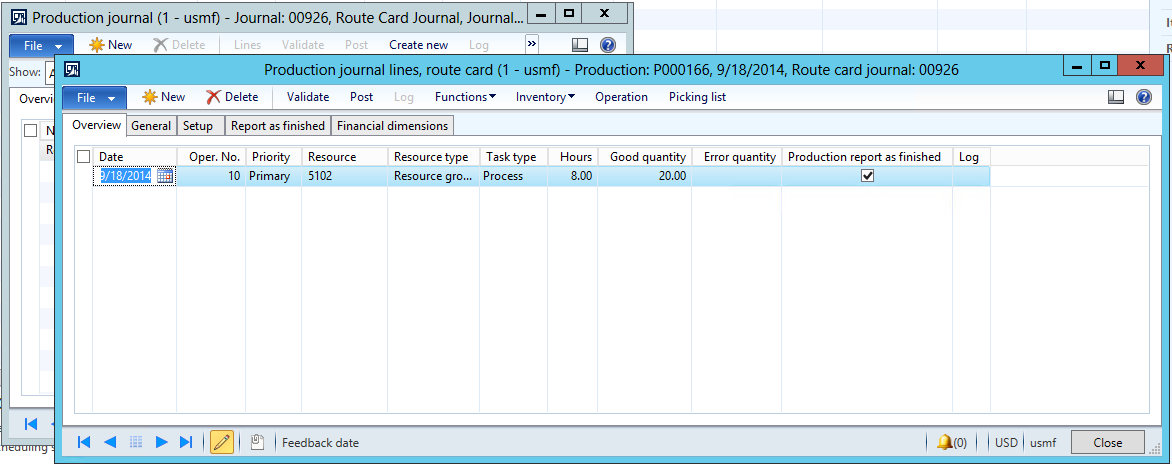

Shannon completes the assembly of the twenty Mini-speakers and reports the quantity as finished in the route card journal:

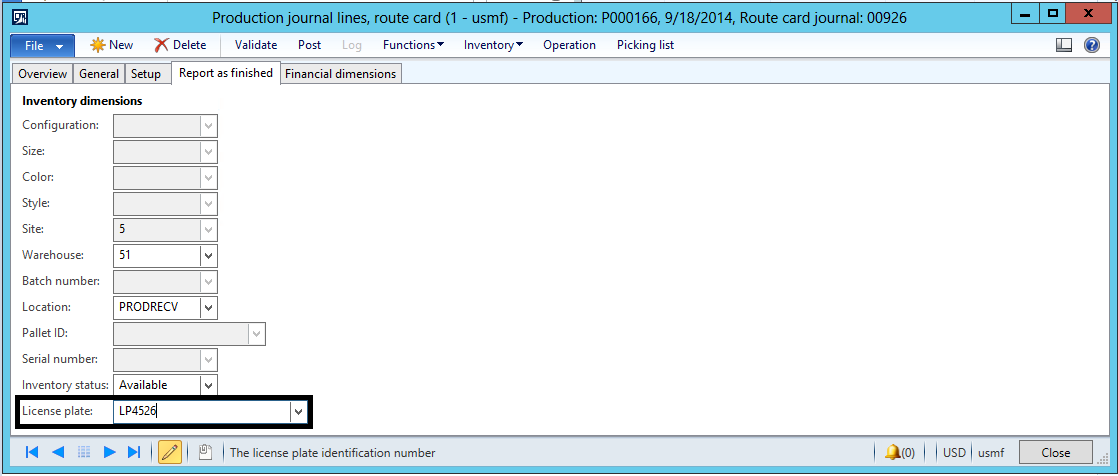

Shannon provides the journal line with a license plate number:

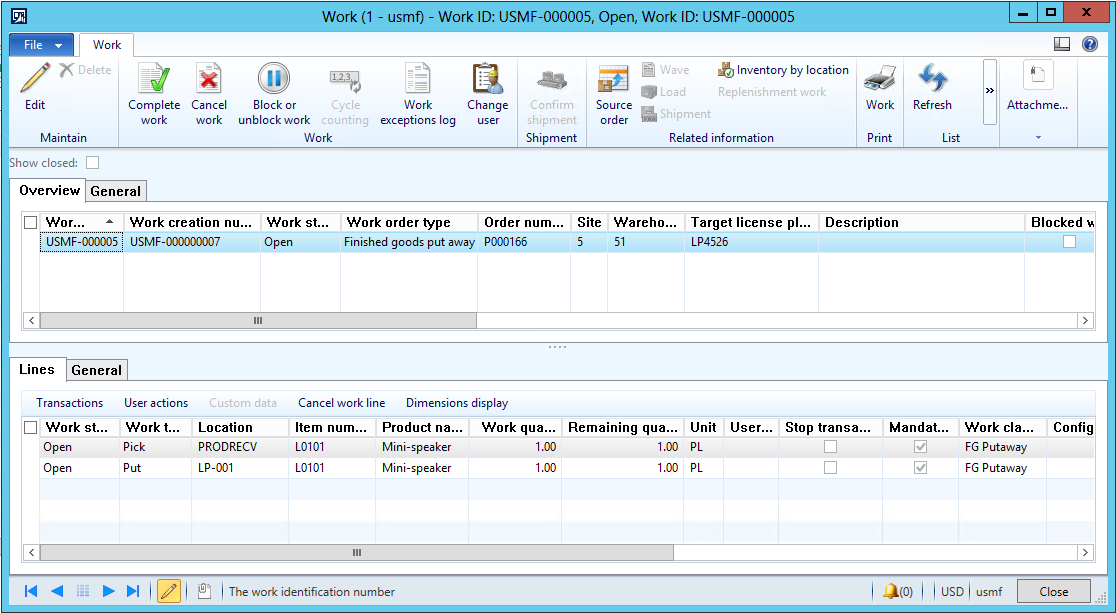

When Shannon posts the journal, put away work is generated:

Advanced scenario : Shannon is working on a production order assembling ten Mini-speakers. Shannon has completed the assembly of eight speakers and reports them as finished in the job registration terminal form and put away work is generated. Shannon completes the assembly of the remaining two speakers but does not have time to report them in the terminal, because she has to rush home. Lars promises Shannon that he will take care of reporting the remaining quantity as finished.

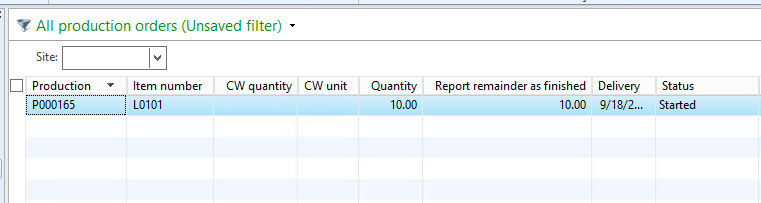

A production order for ten pieces of mini-speakers exists and is in the status Started:

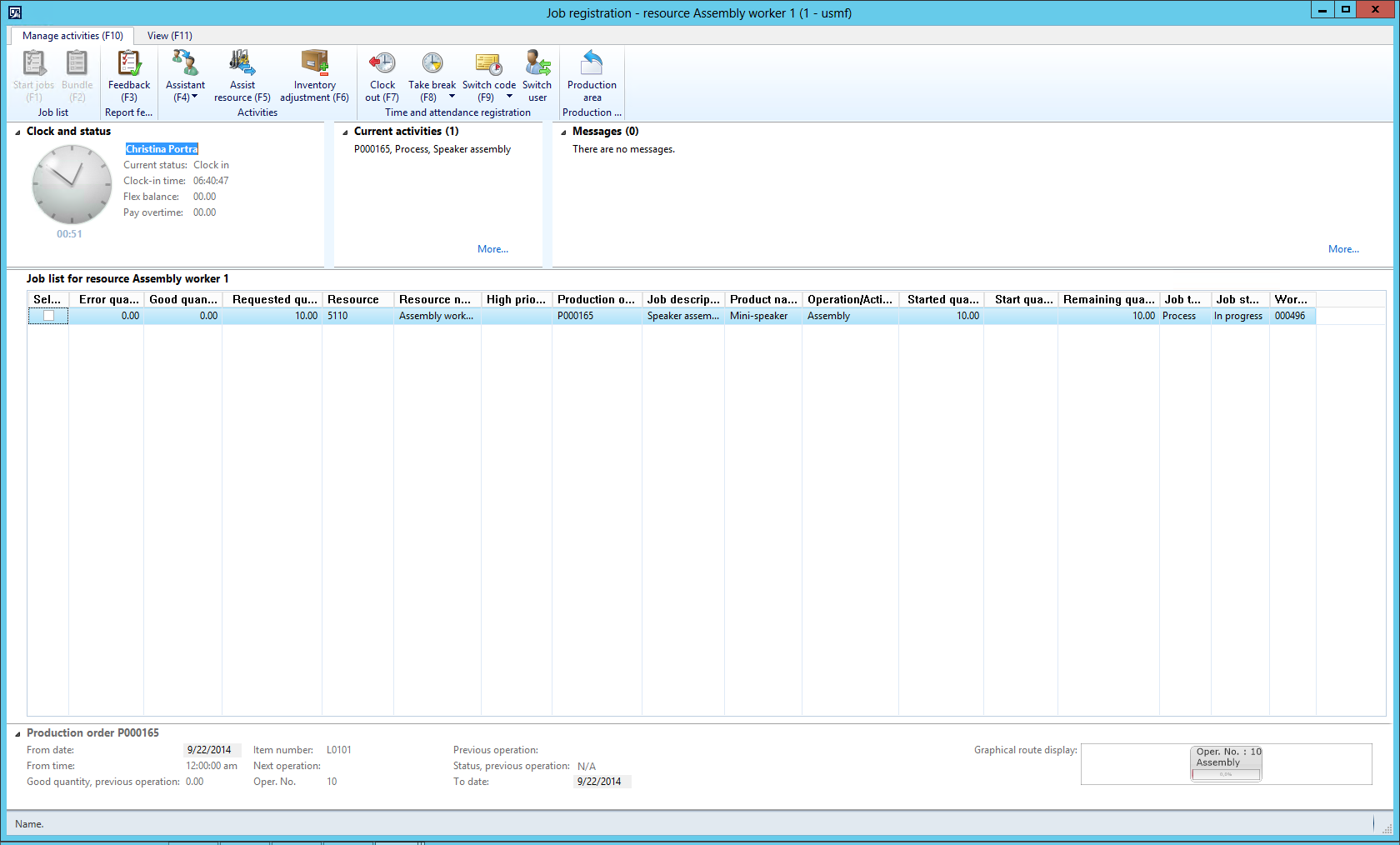

Shannon has started the assembly of 10 mini-speakers:

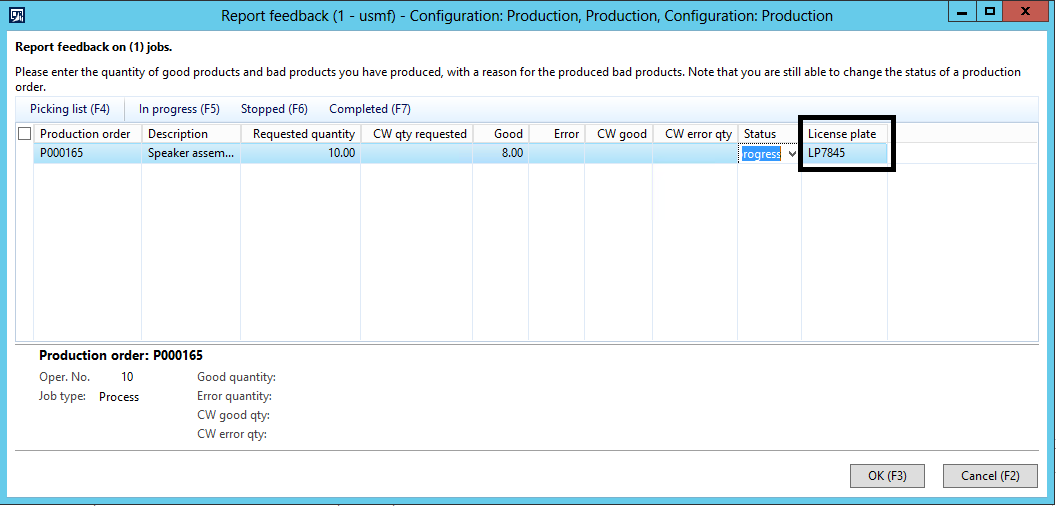

Shannon is now going to report eight pieces as finished from the Job registration form in the manufacturing execution system. In the feedback form Shannon provides a license plate number. This number identifies the goods that Shannon is reporting to the output location of her work cell. The license plate number will be used by the warehouse worker to identify the goods that he is going to put away from the output location to the finished goods locations:

Note: The license plate field is enabled in the feedback form under the following conditions

- The item is enabled for the new warehouse processes

- The shop floor operator is reporting on the last operation in the production route

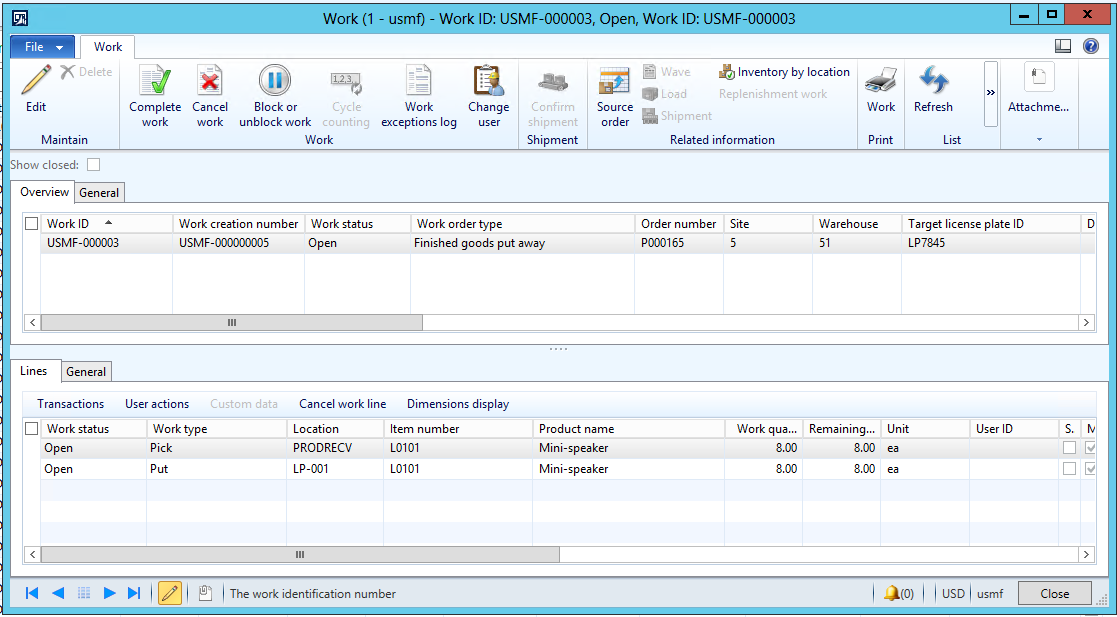

After Shannon has confirmed the feedback of eight pieces of mini-speakers, put away work is generated:

As it can be seen this work suggests that the eight Mini-speakers are put away from the production output location to the finished goods location.

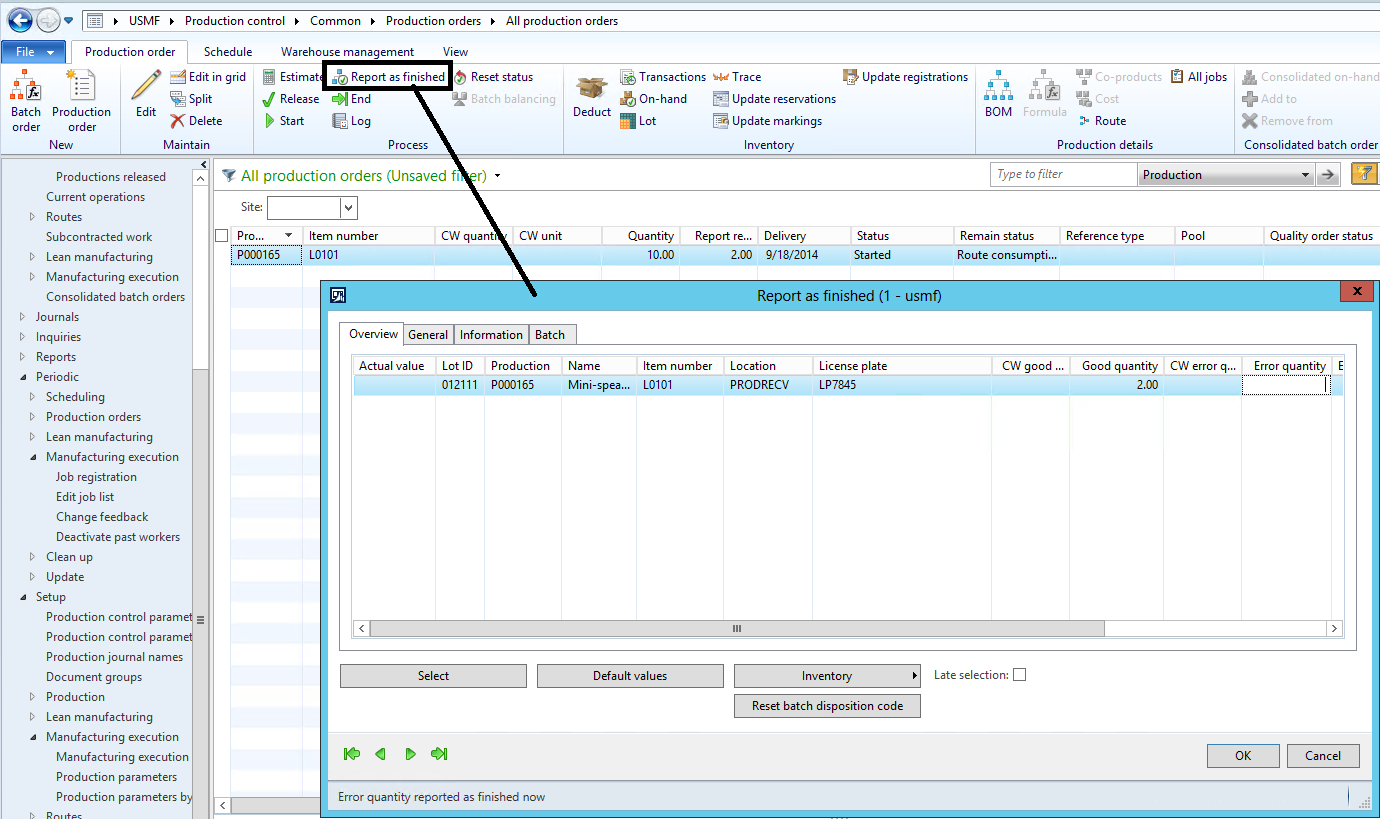

In order to report the remaining two Mini-speakers, Lars opens the production order form and selects the Report as finished function. Here he enters the remaining two pieces and the license plate. In this case he uses the same license plate as Shannon did when she reported the first eight speakers:

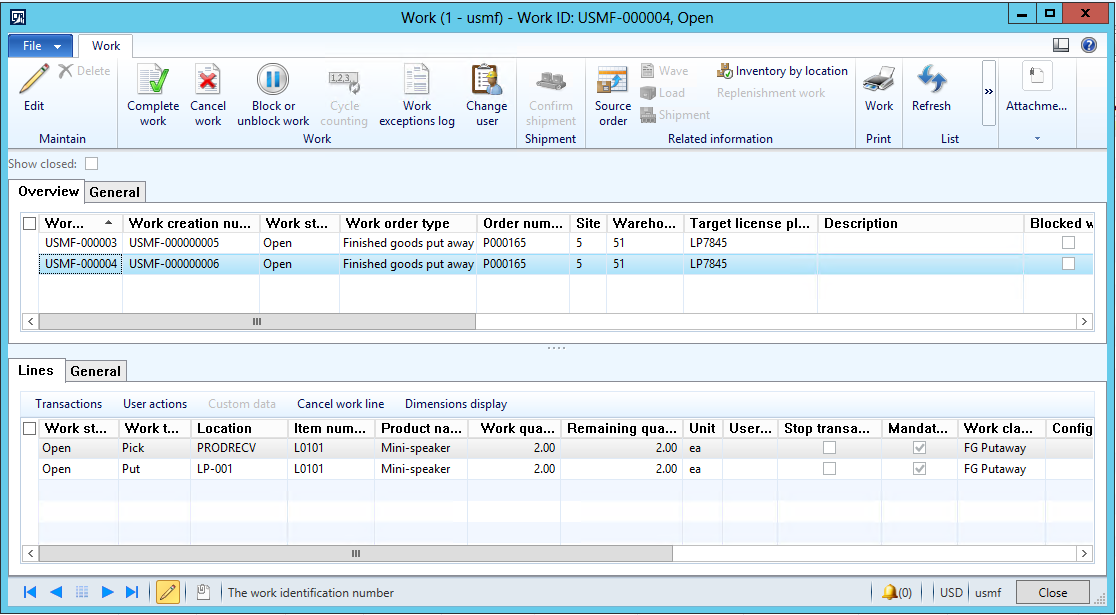

After confirming the report as finished, put away work has been generated for the remaining two speakers that were reported by Lars:

The different options for reporting as finished is outlined in the table below. All these options now supports the generation of put away work:

Option |

Description |

Report as finished |

Dedicated function on the production/batch order form or list page. Has advanced options to for example back flush materials. Typically used by the shop floor supervisor role |

Report as finished journal |

Journal to post the quantity reported as finished for production or batch orders. Typically used by the shop floor operator role |

Job card journal |

Journal to report time and quantity for route operations. Option to report a quantity as finished when reporting on the last operation. Typically used by the shop floor operator role |

Route card journal |

Journal to report time and quantity for production jobs. Option to report a quantity as finished when reporting on a process job for the last route operation. Typically used by the shop floor operator role |

Current operations |

List page showing ongoing operations on the shop floor. Option to report a quantity as finished when reporting on the last operation. Used by the shop floor operator role |

Report feedback in job registration form |

Form that is optimized for manufacturing execution on the shop floor in a kiosk or terminal installation. Option to report a quantity as finished when reporting on the last operation or a process job for the last operation. Used by the shop floor operator role |

Hand held device |

Menu items on hand held device offering reporting production or batch orders as finished. Used by the shop floor operator role |

Summary

In CU8 it is now possible to have put away work generated when reporting quantity on a production or batch order in the Dynamics AX client. For example this can be useful for customers who wants to enable the new warehouse processes offered in the R3 release, but wants to continue to use the shop floor terminal for manufacturing execution, or also want to enable the shop floor supervisor to make corrections.