Configure tracking dimensions

Serial and batch numbers provide companies with the ability to trace their products through Supply Chain Management. The numbers are used for the following purposes:

- Tracing

- Quality assurance

- Warranties

Traceability is useful for quality assurance purposes and when you deal with warranties for a product. The tracing functionality is especially important for items that represent a certain risk, such as medicine or chemicals, where defects in production can lead to item recall. It is equally important for guaranteed items to be able to trace back to the date that the product was manufactured or sold.

Serial and batch numbers allow for this kind of functionality. You can assign serial numbers, batch numbers, or both to an inventory item. Serial numbers are assigned to individual items, where batch numbers are assigned to a set of items.

You can use tracking dimensions to identify and determine how items should be tracked. By using tracking dimensions, you will be able to manage inventory on a detailed level.

A tracking dimension is a required field on every product that you set up in your system. As the name implies, it is used if you need to track an item throughout its life. For example, you might assign batch numbers if there is a need to track an item back to the manufacturing of that item.

Batch numbers apply to a group of items, while a serial number applies to a single item. You can also specify if the batch or serial number is a required field when you process various transactions in the system. In some cases, you might create a tracking dimension if your product requires both a serial number and batch number. You can also have products that have neither dimension assigned to the product.

Product information management > Setup > Dimension and variant groups > Tracking dimension groups

Tracking dimensions are necessary when you need to act based on a recall scenario. For example, if a company has purchased products and the vendor has issued a recall due to some issues with those products. Upon registration of the products prior to placing them in the proper location of a warehouse, you can find the products, pick them, and send them back through a vendor return order.

If a company accepts consignment items from vendors, which means the products belong to a vendor, unless the company changes the ownership of the product, you can enable the Owner dimension and use the Change ownership inventory journal. After the ownership changes, it becomes the company’s liability to process the vendor invoice and provide payment.

Lot ID is the term that refers to a transaction, and not an item dimension such as serial and batch numbers. A Lot ID is assigned automatically to each sales or purchase line when you create it. The number is taken from the number sequence that is associated with the number sequence reference Lot No. in the inventory parameters. You cannot make transactions without a Lot ID being assigned, unlike using batch numbers, when you can select to either use them or not.

Serial and batch numbers are inventory tracking dimensions and can be allocated to products only when the products' tracking dimension group allows for it.

If you select the Serial number control parameter on the Tracking dimensions group page, the system will only allow for inventory movements with a quantity of one.

To use this functionality, select the Serial number control slider for the relevant inventory dimension groups.

When you are physically receiving or updating items that arrived in the warehouse, the physical on-hand quantity plus the arrival quantity cannot exceed one. Physical inventory is automatically selected to handle the control correctly, and usually the Physical negative inventory field on the Inventory model groups page is clear. Therefore, the functionality is unchanged.

The tracking inventory dimensions that are used to track items on the warehouse and outside are:

- Batch number

- Serial number

- Owner

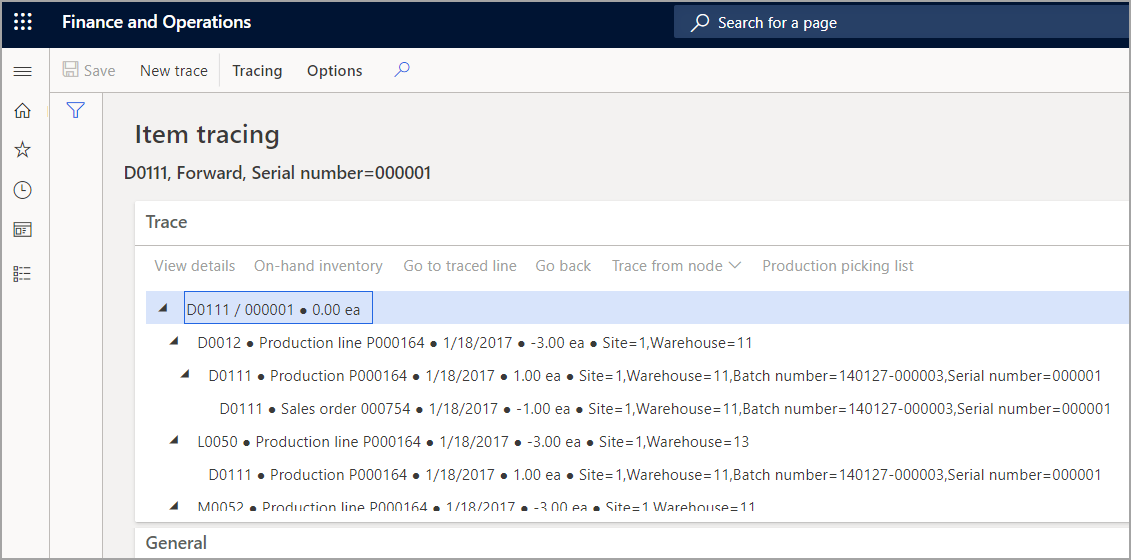

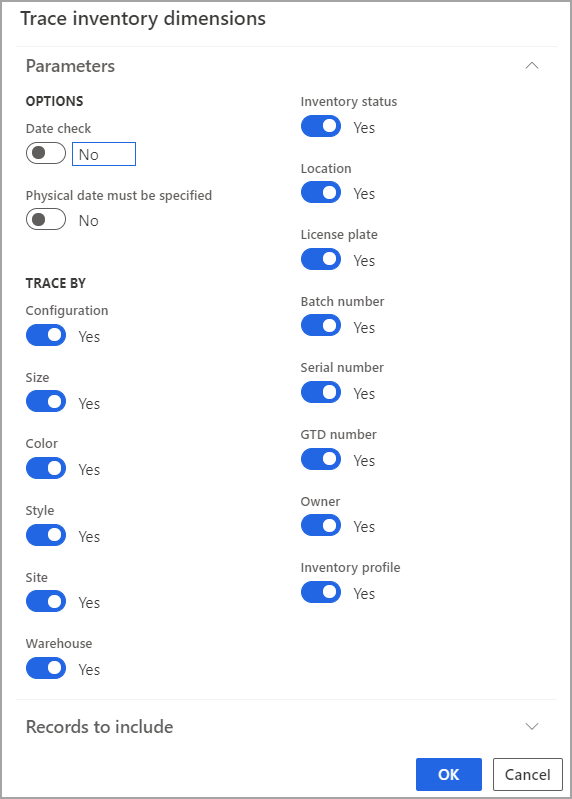

Trace inventory dimensions function

The trace inventory dimensions function not only traces serial and batch numbers, but also provides details of all other dimension values that are associated with the item.

If the parameters for tracing are specified on the Trace inventory dimensions page, you can change the Item number, Record ID, Lot ID, and Dimension number fields by selecting the Select button.

When the Trace inventory dimensions report is run, the result displays in a tree graphic. The Format field shows the format for the transactions.

You can use the Item tracing page to find details such as transactions, associated quality orders, production orders, batch numbers, and more.