Discover enterprise asset management concepts

Asset management enables you to efficiently manage and carry out tasks related to managing and servicing many types of equipment in your company, such as machines, production equipment, and vehicles. Asset management supports solutions across numerous industries.

Asset management terminology and concepts

Before you go further, it’s important to understand key terms and concepts that are used when you're working with asset management.

- Asset – The physical property of an organization, such as buildings, plants, machinery, equipment, and vehicles.

- Asset BOM – Asset bill of materials (BOM) is a list of spare parts and materials used in the lifetime of an asset. An example is the parts that are associated with a conveyer belt. The parts, such as nuts/bolts, motor, the belt, and so on, are all parts and materials of the asset.

- Asset management – The process of managing the lifecycle of physical assets across departments, facilities, business units, and locations to maximize their use, save money, and improve quality and efficiency.

- Asset service levels – Used to define the priority of work orders when maintenance is required on an asset.

- Asset types – Used to manage the maintenance job types (maintenance tasks), asset lifecycle states, counters, asset attributes, condition assessment templates, and asset models that can be selected for an asset. When you create an asset, you must specify the asset type.

- Attributes – Describes the properties of an asset, including color, size, and dimensions.

- Counters – Used to capture the usage of an asset, such as tracking the number of production hours, quantity produced on an asset, and mileage. Maintenance orders can be established on assets based on the counters that are defined on those assets. For example, if a motor has been running for 3,000 miles, an order can be placed for maintenance when that motor reaches 3,000 miles.

- Counter types – Used to make counter registrations on assets. These types could be production hours, quantity produced, mileage, and temperature.

- Functional location – Represents an area where an asset is or can be installed.

- Functional location lifecycle model – This lifecycle model determines the process or flow of lifecycle states for a functional location.

- Functional location lifecycle state – Defines the various states that a functional location can go through during its lifecycle. These states can include Created, Active, and Ended.

- Functional location type – Used to manage functional location requirements, such as how assets are installed. Examples of a functional location type include area, plant, yard, and warehouse.

- Maintenance – The continuous strategy for improving the availability, safety, reliability, and longevity of physical assets.

- Maintenance requests – Requests made to a manager or planner indicating that an asset needs maintenance or repair.

- Maintenance schedule – Any repair upkeep work performed on an asset within a set timeframe. It details what maintenance tasks are performed and by whom. Based on how maintenance schedules are set up, they can occur at repeating intervals or in response to a work order.

- Work orders – Maintenance orders placed in the system that describes the maintenance or repair that is needed on an asset and assigns the appropriate resources to complete the maintenance request.

Key components of asset management

Functional locations

Functional locations are used to track physical assets and their locations. Examples of locations include plants, warehouses, yards, and office buildings.

- They are structured hierarchically, and locations can have sub locations.

- The structure of functional locations cannot be changed after they have been created. In other words, locations can’t move.

- How you build your hierarchy of functional locations depends on your company's organizational structure and preferences.

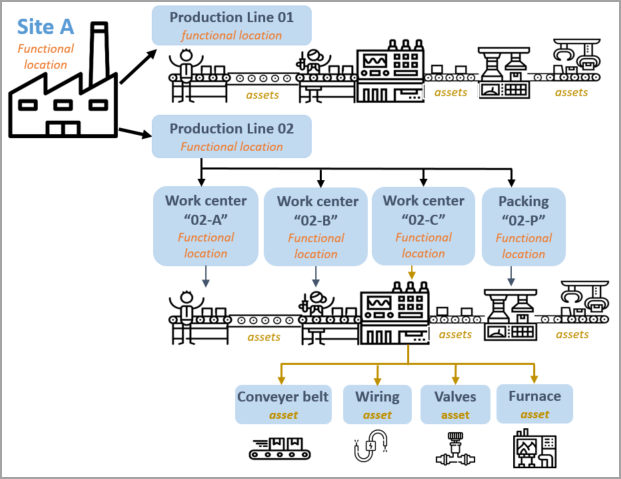

Following is an example of a functional location based on a site.

This example features the Munson's Pickles and Preserves Farm company. This sample is a salsa plant (titled Site A) and is a functional location where assets installed at this functional location are used to make salsa.

Production Line 01, another functional location, creates the labels for the jars and attaches them to the jars by using machinery (assets).

Production line 02, functional location, is where they are making the salsa at the various work centers. These centers, too, are functional locations that use the following assets:

- Work center 02-A prepares the ingredients for the salsa.

- Work center 02-B mixes the ingredients and adds spices together.

- Cooking the salsa occurs at the functional location Work center 02-C.

- Packing 02-P is where the labeled jars are packed for delivery.

The following list summarizes functional locations:

- Functional locations are the places where assets are “installed” or located.

- Functional locations can be established hierarchically to include sub locations.

- Sub locations can have sub locations.

- Assets are the equipment used, such as the conveyer belt, machinery to cook the salsa, and so on.

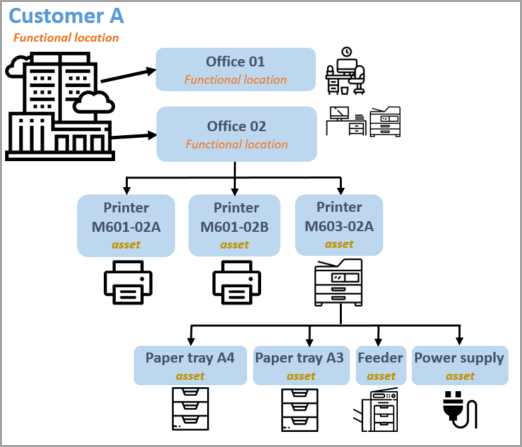

The following example shows a functional location based on a customer.

This example shows a functional location where a corporate office is Customer A. Within Customer A, offices represent locations. In this example, Office 01 and Office 02 could be a desk or work area. Office 02 is a work area with printers and assets installed.

Assets

Assets are the physical equipment and machinery, such as conveyer belts, forklifts, and the parts and tools that are used to support and maintain the physical asset. The following list describes key information about assets:

Assets can be organized in a hierarchical structure, or they can be organized by functional locations.

Assets can be installed on functional locations and, if needed, can be moved to or installed on other functional locations. By using the example from the preceding image, the printer M601-02A, which is an asset, is located at the functional location of Company A and in Office 02 and can be moved to a different location, such as Company A and then moved to Office 01.

Assets can have sub assets, such as spare parts for the asset.

Asset costs always follow the location of the asset.

- If you install an asset on a new functional location, the asset automatically uses the financial dimensions that are related to the new functional location.

- This process ensures that asset costs are always related to the functional location that the asset is currently installed on.

- This automatic handling of financial dimensions helps guarantee complete tracking of costs when your company does project controlling and reporting on functional locations.