Set up manufacturing for the warehouse

In a location that is set up with directed put-away and pick, each item transaction is processed by bin. Specifically, before you can post consumption, you need to first pick the components in the warehouse and then move them to the production zone.

When you post output, the finished items are automatically placed on the from-production bin. To make the finished items available for picking, you need to move them into the warehouse.

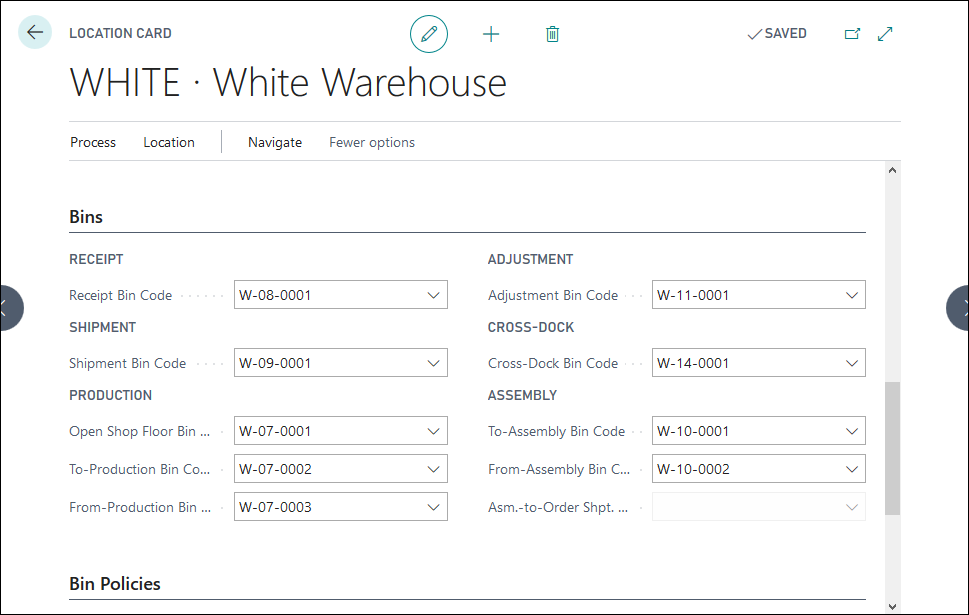

To set up the production bins on the location card, follow these steps:

Select the Search for page icon in the upper-right corner of the page, enter locations, and then select the related link.

Open the location card where you want to set up the production bins.

Expand the Bins FastTab and enter the following bins:

Open Shop Floor Bin Code - Specifies the bin that functions as the default open shop floor bin. The open shop floor bin is used with flushing methods, forward and backward.

To-Production Bin Code - Specifies the bin in the production area where components that are picked for production are placed by default before they can be consumed.

From-Production Bin Code - Specifies the bin in the production area, where finished end items are taken from by default, when the process involves warehouse activity.